Home

Media

Media

Citizen Metal Has Two Lines For Making Hot-Rolled Seamless Steel Pipes And Three Lines For Making Cold-Drawn Seamless Steel Pipes. Together, These Lines Can Make 100,000 Tonnes Of Pipes Per Year. The Pipes Have Diameters That Range From 73mm To 630mm. From About 21 Mm Outside Diameter To About 178 Mm Outside Diameter, Both Continuous Rolling And The Push Bench Method Are Used. The Uncoiling Machine, The Butt Welder, The Loop, The Straightening Machine, And The High Frequency Equipment Are All Used By A Pipe-Welding Machine To Join Pipes Together. Welded Steel Pipes Are Made Using The International Standard. This Is Not Only Cheap, But Also Used By Some Of The Most Well-Known Companies In The World.

We manufacture and have in stock a selection of premium steel pipes, tubes, and tubing at Citizen Metals Pvt. Ltd. We carry pipes and tubes in specific grades including Duplex 2205 and Super Duplex 2507 as well as SS304, SS316L, SS316, SS317L, and SS321. Our warehouses are expressly constructed to fulfil the needs of our customers in Africa, Europe, and the Middle East, and we are able to export up to 50 tonnes of duplex 2205 stainless steel pipe the same day.

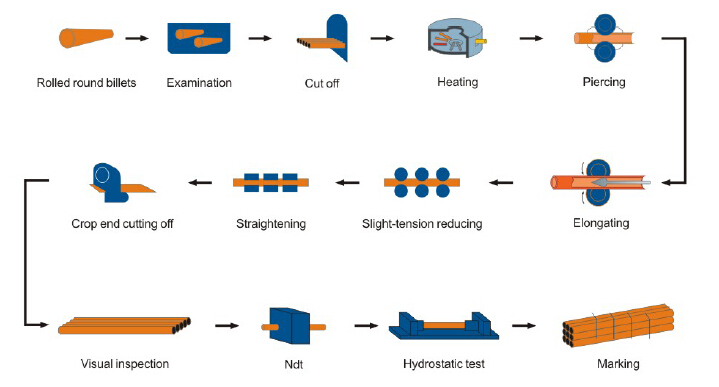

STAINLESS STEEL PIPE HOT ROLLED MANUFACTURING

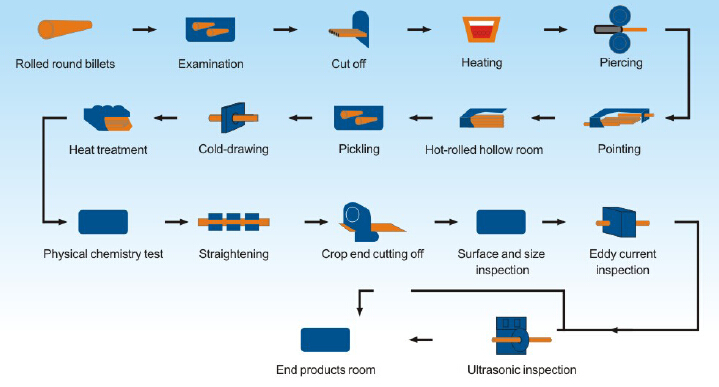

STAINLESS STEEL PIPE COLD DRAWN PROCESS

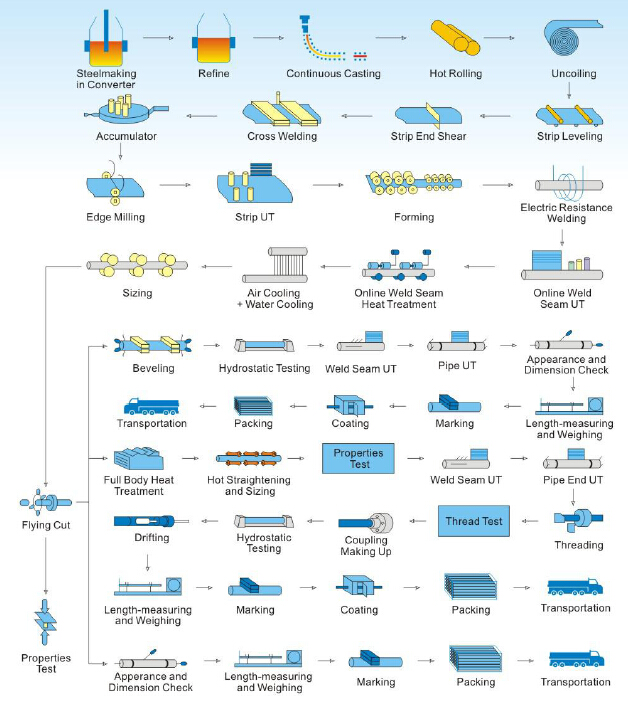

ERW STAINLESS STEEL PIPE MANUFACTURING PROCESS

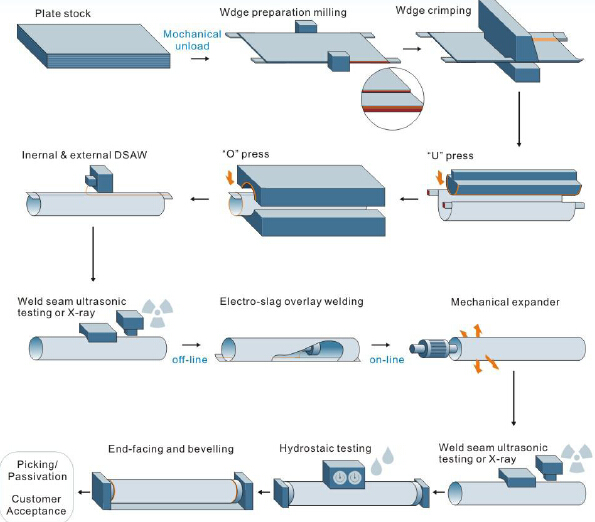

LSAW STEEL PIPE MANUFACTURING PROCESS