Buttweld Pipe Fittings - Bends

Explore our selection of Superior Bends Buttweld Fittings

Superior Quality Bends crafted for high Durability and Efficiency

Citizen Pipe Fittings is a renowned manufacturer and exporter of Bends Buttweld Pipe Fittings. These fittings are designed and produced in compliance with national and international quality standards, ensuring their durability and high quality

Available in a range of sizes, types, and bending radii, bend Buttweld Fitting Exporters cater to a broad spectrum of applications. They find extensive use in diverse industries including oil and gas, chemical, power plants, construction, water supply systems, and the paper & pulp industry

The standout features of these fittings encompass their enduring durability and compliance with both national and international quality standards. The specifications and grades of the fittings can vary, contingent on the specific product model and its application. For precise details, it is always advisable to refer to the product documentation

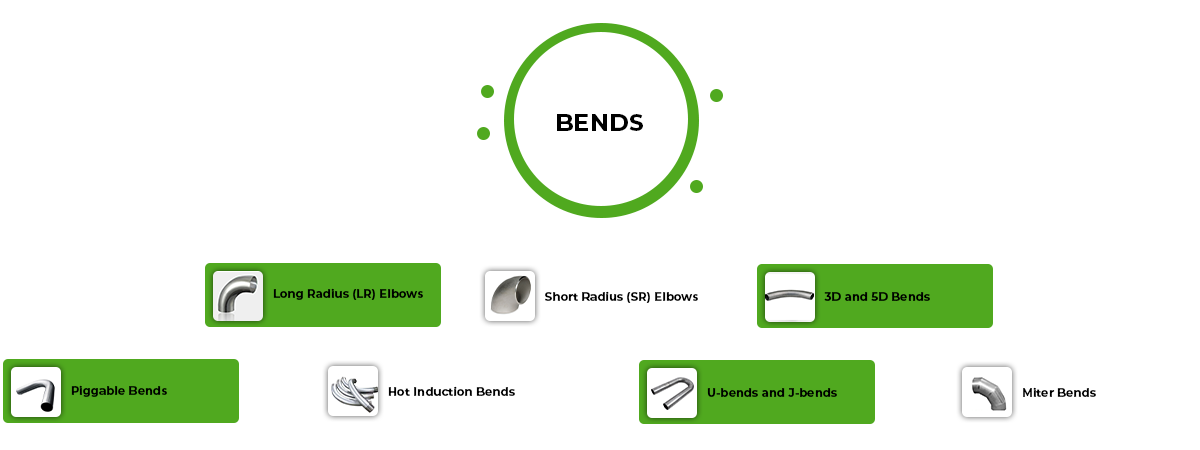

Types of Bends

Buttweld pipe fittings, particularly bends, come in a variety of types to accommodate different needs and applications. Here are some of the common types

- Long Radius (LR) Elbows : These are the most common type of bends. They have a radius equal to 1.5 times the diameter of the pipe. They offer less resistance to flow and hence are suitable for low-pressure applications

- Short Radius (SR) Elbows : These bends have a radius equal to the diameter of the pipe. They are used in areas with space constraints. However, they offer more resistance to flow and are suitable for high-pressure applications

- 3D and 5D Bends : These bends are named based on the radius of curvature. A 3D bend has a radius of curvature three times the diameter of the pipe, while a 5D bend has a radius five times the diameter. These bends are used in high-pressure applications where long radius bends are not feasible

- Piggable Bends : These bends are designed to allow the passage of a ‘pig’ - a device used for cleaning or inspecting the pipeline. They have a large radius and a straight section at both ends

- Hot Induction Bends : These bends are made by heating a section of the pipe and then bending it to the desired angle. They are used in high-temperature and high-pressure applications

- U-bends and J-bends : These bends are used in heat exchanger tubes. U-bends have a U shape, while J-bends resemble the letter J

- Miter Bends : These are fabricated bends, made by cutting pipe sections at an angle and welding them together. They are used when standard bends are not available

Key Features of Bends Buttweld Pipe Fittings

- Durability : These fittings are made from high-quality raw materials, which ensures their long-lasting durability

- Quality : The fittings are produced in accordance with national and international quality standards

Specifications

| Specification | Description |

|---|---|

| Size | Ranges from 1/2"NB TO 48"NB IN |

| Type | Seamless / ERW / Welded / Fabricated |

| Form | Hot Bend, Long Radius Bend, Piggable Bend, 3D, 5D, U, J, Customized |

| Bending Radius | R=10D,8D,6D, 5D,1D, 2D, 3D or Custom |

Grades

| Specification | Description |

|---|---|

| Stainless Steel | ASTM A403 WP Gr. 904L, 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, |

| Carbon Steel | ASTM A234 WPB, A420 WPL3, A420 WPL6, MSS-SP-75 WPHY 42/46/52/ 56, 60, WPHY65/ 70 |

| Alloy Steel | ASTM A234 WP91,WP1, WP5, WP9, WP11, WP22, |

Applications

Buttweld pipe fittings, specifically bends, are integral components in a variety of industries. Here are some of their applications across different sectors

- Oil and Gas Industry : In the oil and gas industry, buttweld pipe fittings are used extensively in the transportation of crude oil and natural gas. They are used in the construction of both onshore and offshore pipelines. The bends allow for directional changes in the pipeline, accommodating the natural contours of the earth and any man-made structures

- Chemical Industry : The chemical industry uses buttweld pipe fittings in their complex network of pipes that carry chemicals and gases. These fittings, including bends, are resistant to corrosion and can withstand the harsh chemicals being transported

- Power Generation : In power plants, especially nuclear and thermal, buttweld pipe fittings are used in the coolant systems, steam lines, and feedwater systems. The bends are crucial in these settings as they allow for the efficient flow of fluids

- Food and Beverage Industry : In the food and beverage industry, buttweld pipe fittings are used in the process lines. They help maintain hygiene standards as they do not have any pockets where food particles can get trapped

- Hot Construction Industry : In the construction industry, buttweld pipe fittings are used in the plumbing systems of buildings. The bends are used to change the direction of the pipes, allowing for the efficient distribution of water

- Shipbuilding Industry : In shipbuilding, buttweld pipe fittings are used in the construction of ships’ hulls and in the piping systems of the ships. The bends are used to navigate the complex structure of the ship

- Automotive Industry : In the automotive industry, buttweld pipe fittings are used in the exhaust systems of vehicles. The bends are used to direct the exhaust gases safely out of the vehicle