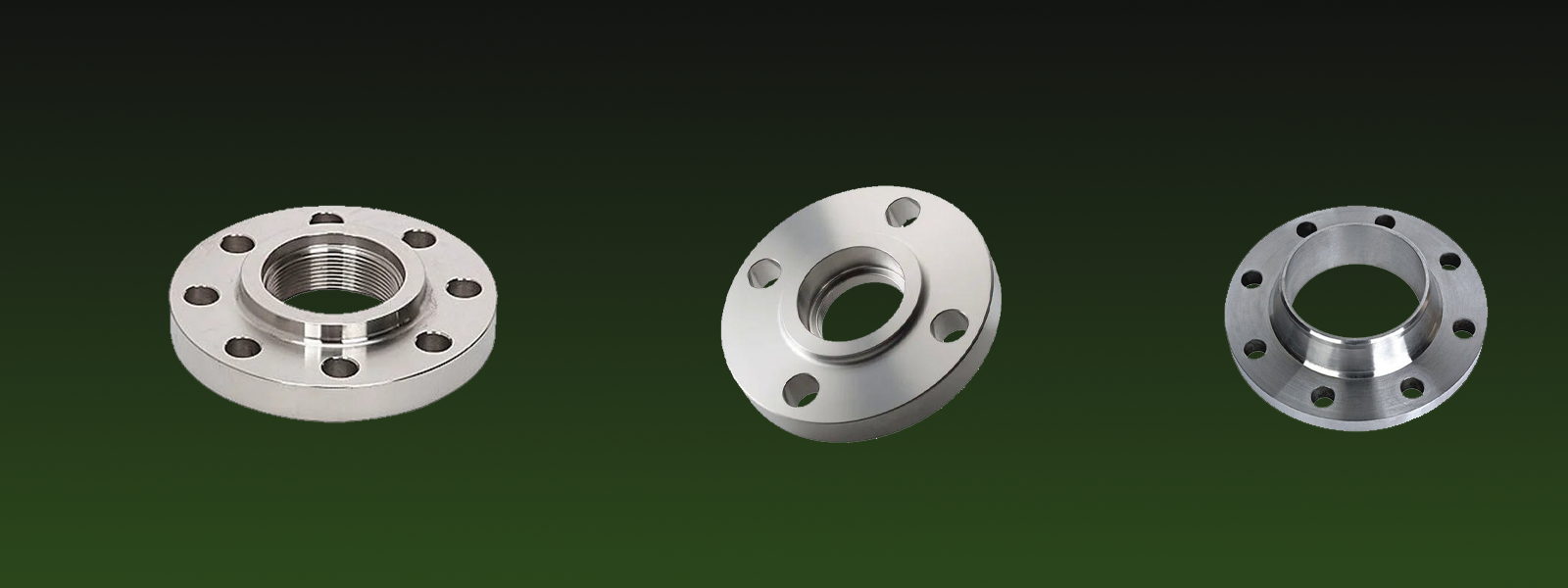

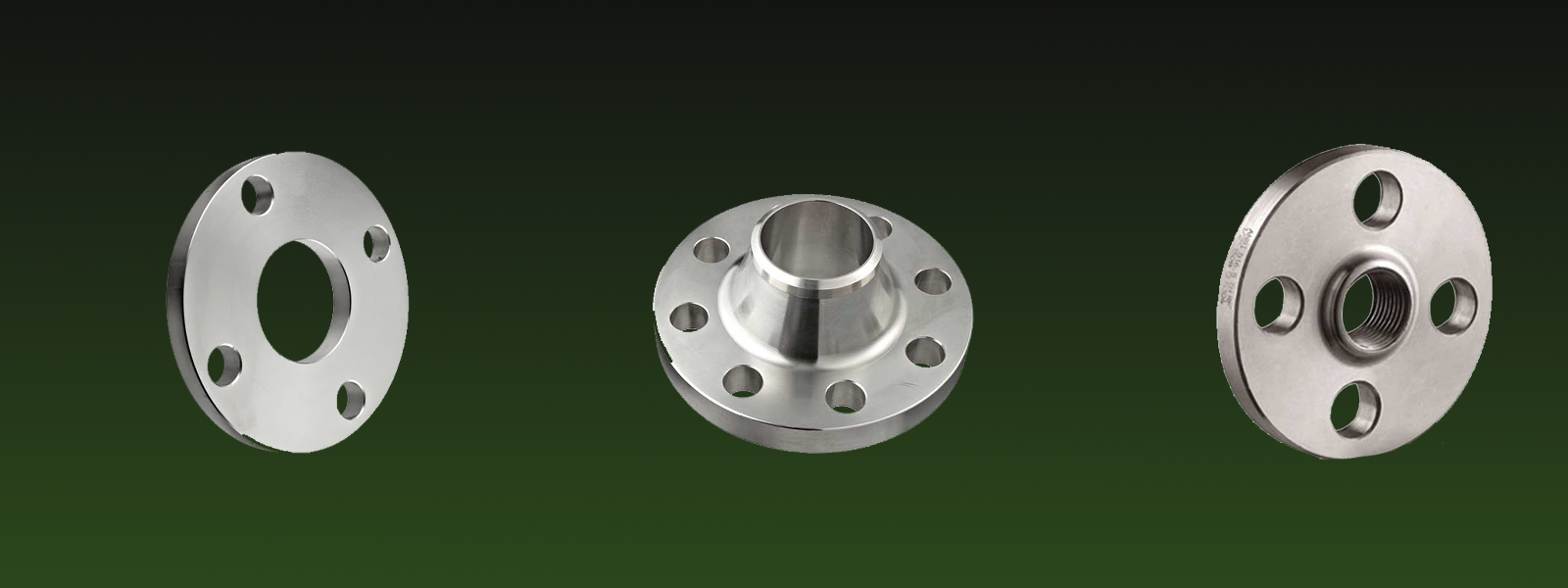

In industrial applications where resistance to corrosion and reliability are critical, Hastelloy flanges have become a preferred choice. These high-performance components are widely used in industries such as chemical processing, marine engineering, and power generation due to their excellent resistance to oxidizing and reducing agents. Citizen Pipe Fittings, a leading manufacturer, supplier, and exporter in Mumbai, India, specializes in providing Hastelloy flanges and fittings that meet stringent quality standards like ASTM A182. This article details the connection method of waterproof Hastelloy flanges to pipes, ensuring optimal performance and durability.

Importance of Hastelloy Flanges in Piping Systems

Hastelloy flanges, known for their exceptional resistance to harsh environments, are often used in applications involving high pressure, temperature, and corrosive substances. These flanges, particularly those manufactured to ASTM A182 standards, ensure reliable connections between pipes and other equipment while maintaining the integrity of the system. Their durability and versatility make them an essential component for industries aiming to achieve long-term efficiency.

Preparing for Connection: Key Considerations

Before connecting a Hastelloy pipe flange, certain preparatory steps must be undertaken to ensure a secure and waterproof installation :

- 1. Inspecting the Flanges and Pipes : Check the Hastelloy flanges and pipes for any visible defects, such as cracks, dents, or warping. Flawless surfaces are crucial for a leak-proof connection.

- 2. Cleaning the Components : Remove dirt, grease, or other contaminants from the flange and pipe surfaces. This ensures proper sealing and reduces the risk of corrosion over time.

- 3. Aligning the Components : Proper alignment is crucial for maintaining the integrity of the connection. Misaligned components can lead to stress on the joint and eventual failure.

Connection Methods for Hastelloy Flanges

There are several methods to connect Hastelloy flanges to pipes, depending on the application requirements and flange type. Here are the most common techniques :

1. Welding

Welding is the most reliable method for connecting Hastelloy flanges to pipes. This method creates a strong, permanent, and waterproof joint.

- Butt-Welded Connection :

- Align the Hastelloy pipe flange with the pipe.

- Use a TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding process for precise and clean welds.

- Ensure the weld penetrates the entire joint for maximum strength .

- Socket-Welded Connection :

- Insert the pipe into the flange socket.

- Apply a fillet weld around the joint to secure the connection.

- This method is ideal for smaller-diameter pipes and systems requiring high pressure.

2. Bolted Connection with Gaskets

Bolted connections are another popular method for joining Hastelloy flanges and fittings. This technique allows for easy assembly and disassembly during maintenance.

- Steps for a Bolted Connection :

- Place a gasket between the mating surfaces of the Hastelloy flanges.

- Align the bolt holes of the flanges and insert the bolts.

- Tighten the bolts in a crisscross pattern to ensure uniform pressure distribution.

- Use a torque wrench to achieve the specified torque level, preventing under-tightening or over-tightening.

3. Threaded Connection

Threaded connections are commonly used for smaller-diameter pipes where welding is not feasible.

- Procedure :

- Ensure that both the Hastelloy pipe flange and the pipe threads match.

- Apply a suitable thread sealant or Teflon tape to prevent leaks.

- Screw the flange onto the pipe and tighten it securely.

Ensuring a Waterproof Seal

To achieve a waterproof connection with Hastelloy flanges, the following best practices should be adhered to :

- Select the Right Gasket : Choose gaskets compatible with the operating conditions, such as temperature, pressure, and the type of fluid or gas being transported.

- Apply Proper Torque : Use calibrated tools to tighten bolts to the manufacturer’s recommended torque values, ensuring an even and effective seal.

- Regular Maintenance : Periodically inspect the flange connections for signs of wear or leakage and re-tighten bolts if necessary.

Advantages of Hastelloy Flanges

- Corrosion Resistance : Hastelloy flanges exhibit excellent resistance to pitting, crevice corrosion, and stress corrosion cracking.

- High Strength : These flanges maintain their structural integrity under extreme pressure and temperature conditions.

- Versatility : Suitable for various industrial applications, from chemical processing to marine engineering.

- Compliance with Standards : Products like ASTM A182 flanges ensure quality and reliability.

Why Choose Citizen Pipe Fittings?

As a trusted manufacturer, supplier, and exporter in Mumbai, India, Citizen Pipe Fittings offers a comprehensive range of Hastelloy flanges and fittings that cater to diverse industrial needs. With a commitment to quality and customer satisfaction, the company ensures that its products meet international standards, including ASTM A182.

By sourcing your Hastelloy flanges from Citizen Pipe Fittings, you benefit from.

- Superior material quality

- Precision manufacturing

- Competitive pricing

- Timely delivery.

Conclusion

Connecting waterproof Hastelloy flanges to pipes is a straightforward process when following the appropriate methods and best practices. Whether through welding, bolted connections, or threaded joints, the reliability and performance of Hastelloy flanges are unmatched. With their exceptional corrosion resistance and strength, these components ensure long-lasting and leak-proof piping systems.

For high-quality Hastelloy flanges and fittings, look no further than Citizen Pipe Fittings. Backed by years of expertise and a strong commitment to excellence, they deliver solutions tailored to your industrial requirements. Reach out today to explore their extensive range of Hastelloy flanges, compliant with ASTM A182 standards.