Creating branch connections is a fundamental aspect of designing and building effective piping systems. In many industrial scenarios – such as adding valves to control flow, integrating instrumentation for monitoring, branching into smaller lines, or changing flow direction entirely – Olet-style fittings (also known as branch connection fittings or piping branch connections) offer a robust and frequently cost-effective solution. These specialized fittings provide a reliable and reinforced point of connection directly to the larger, primary pipe. Citizen Pipe Fittings provides a wide range of Olets including Stainless Steel Olets in various materials, sizes, and connection types to meet the diverse requirements of even the most demanding piping projects

Key Features and Types of Branch connections

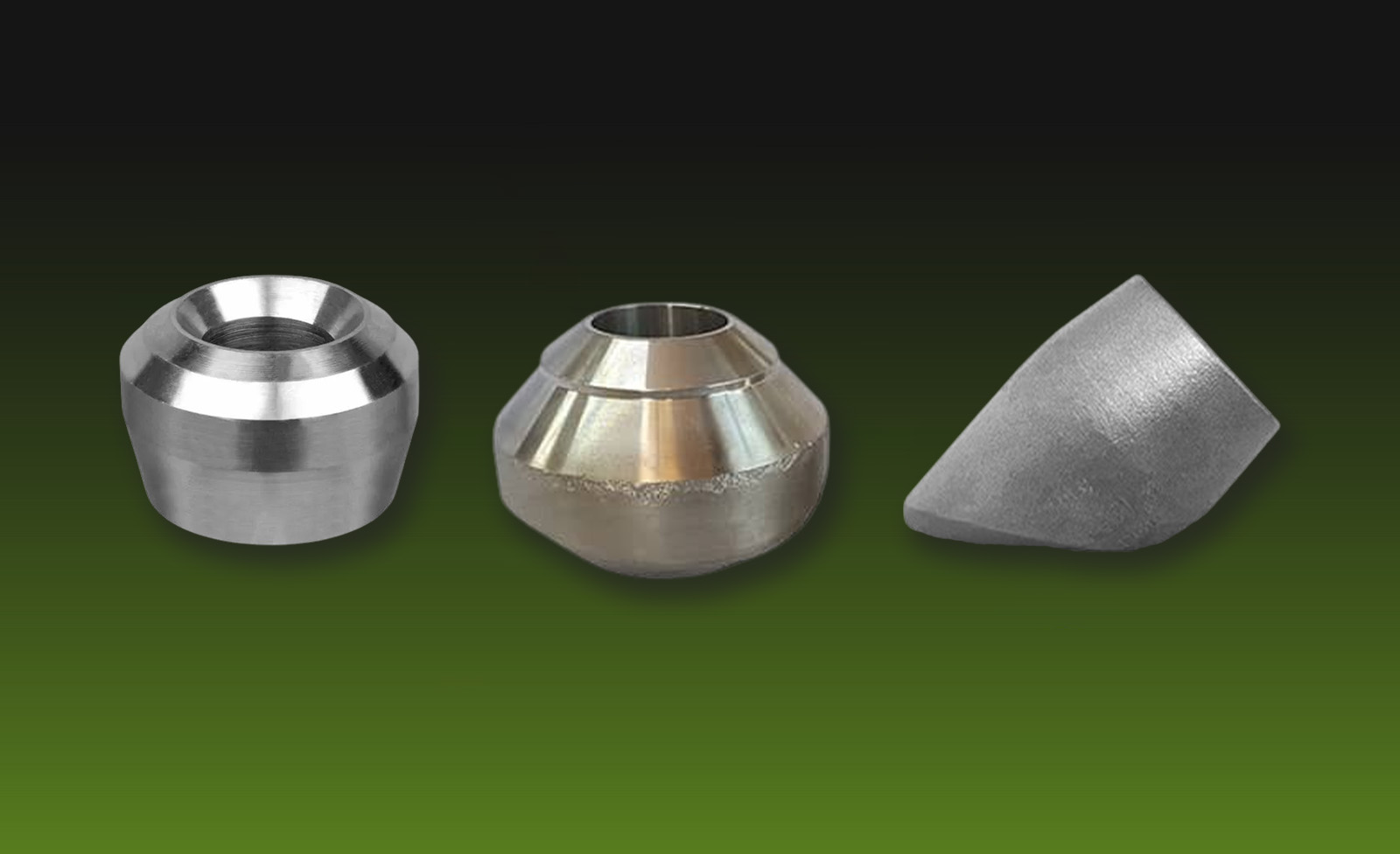

Olets are specialized fittings designed for perpendicular branch connections. Their reinforced construction provides inherent strength and leak resistance

- Weldolets : As the most common piping Olet , they provide maximum strength and leak resistance. A full-penetration butt weld directly fuses the WeldOlet to the main pipe, creating a seamless, robust connection. Ideal for high-pressure, critical systems, or applications where permanent installation is required

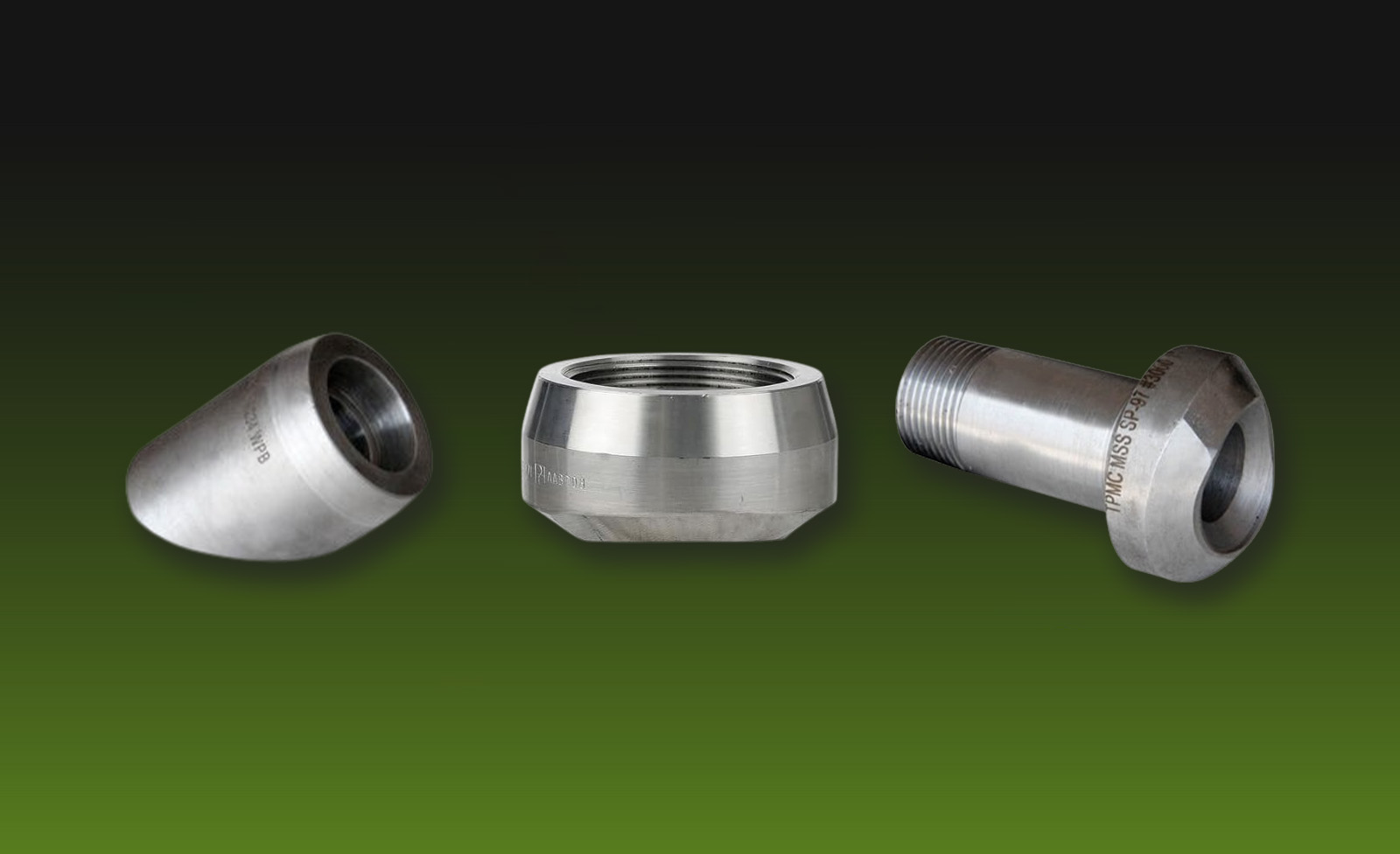

- Threadolets : Prioritize easy installation and potential removability. Threadolet allows them to be installed and removed without specialized welding equipment. Best suited for smaller branch lines, non-critical systems, or applications where maintenance access may be a concern

- Sockolets : Offer a balance of strength and ease of installation. A socket weld joins the SockOlet to the pipe, providing a secure and reliable connection suitable for high-pressure or high-stress applications. They are sometimes preferred over WeldOlets when faster installation is beneficial

- Elbolets : Streamline piping systems by combining an outlet and an elbow function. Elbolet is used when you need to both change flow direction (typically 90 degrees) and create a branch connection simultaneously, minimizing the number of individual fittings required

- Latrolets : Specifically designed for branch connections at a 45-degree angle from the main pipe run, Latrolet may be used to follow specific piping layouts or to avoid obstacles within a system

Selection criteria of Olets

Olets are a popular choice for creating reliable and robust branch connections, but with a variety of options available, selecting the right Olet requires careful consideration. Some of the selection criteria are

- Materials :

- Carbon Steel : Cost effective and widely used for general purpose applications

- Stainless-Steel : Offers superior corrosion resistance for demanding environments. Consider Stainless-Steel Olets specifically if dealing with harsh chemicals and high temperatures

- Alloy Steel : Provides additional strength and durability for high-pressure or high-temperature applications

- Size and Pressure Rating : Olets come in various sizes to match the diameter of your primary pipe. Additionally, they have specific ratings that indicate their maximum allowable operating pressure. Always ensure that the Olet you choose is compatible with both the pipe size and the pressure requirements of your systems

- Branch Connection Type : There are different Olet styles, each offering a unique way to connect the branch line to the main pipe. Consider the size of the branch line you'll be connecting and ensure the Olet's branch outlet diameter is compatible. Additionally, the Olet's run size should match the diameter of your main pipe

- Schedule (Wall Thickness) : Pipes and Olets come in different schedules, indicating wall thickness. Choose an Olet schedule that aligns with the schedule of your primary pipe for optimal strength and compatibility

- Manufacturer's Specifications : Always refer to the manufacturer's specifications for specific details about the Olet's pressure rating, temperature limitations, and any additional considerations for proper installation and use

Advantages and Limitations of Olets

- Advantages : Olets shine for reliable branch connections in pipes. Their design reinforces the branch point, making them strong for high-pressure and critical applications. Compared to complex methods, Olets offers a cost-effective solution. They come in various materials (carbon steel, stainless steel) and connection styles (welding, threaded) to suit your project's needs

- Limitations : Olets, while strong, have some drawbacks. The most common welding olets create permanent connections, making future disassembly tricky. Proper installation, especially welding, requires skilled labor to ensure leak-proof connections. Additionally, some Olet types may not be ideal for extremely high-pressure applications. Consider these limitations when choosing Olets for your piping project

Installation Best Practices

- Cleanliness : Thoroughly clean the pipe and Olet mating surfaces before installation

- Beveling : Prepare pipe ends for welding as needed, following proper procedures

- Alignment : Precisely align the Olet for optimal fit and weld quality

- Welding Expertise : Use qualified technicians for welding, especially in high-pressure or critical systems

- Inspection : Carefully inspect welds or threaded connections for any defects before putting the system into operation

Case Studies of Olets

- Chemical Processing Plant :

- Challenge : A chemical processing plant needed a reliable and secure way to connect pressure gauges to a high-pressure pipeline carrying corrosive chemicals. Standard taps were not strong enough to handle the pressure, and a flanged connection would be too bulky and expensive

- Solution : Stainless steel welding olets were installed. Their reinforced design offered the necessary strength for the high pressure, and the stainless steel material provided superior corrosion resistance against the harsh chemicals. This ensured a leak-proof and reliable connection for the pressure gauges

- Power Plant :

- Challenge : A power plant required branch connections for temperature control valves in their main steam line. These valves were critical for maintaining safe and efficient operation

- Solution : Alloy steel socket welding olets were chosen. The high-pressure rating of the alloy steel olets matched the demands of the steam line, and the socket welding design allowed for easier alignment during installation compared to standard welding olets. This provided a secure and efficient connection for the temperature control valves, ensuring proper operation of the power plant

- Building Water Supply System :

- Challenge : A new building required branch connections for fire sprinkler systems to be integrated into the main water supply line. Disassembly for future maintenance might be necessary

- Solution : Threaded olets were installed. These olets offered a cost-effective solution for the lower pressure requirements of the sprinkler system. Additionally, the threaded connection allowed for easier disassembly compared to welded olets, facilitating future maintenance needs

Citizen Pipe Fittings: Your Trusted Olet Source

Citizen Pipe Fittings understands the importance of high-quality Olets for reliable piping systems. That’s why we prioritize both quality and customer service in everything we do. Our extensive inventory offers a wide selection of Olets in various sizes, materials, and configurations to ensure we have the ideal solution for your specific piping project requirements. If you need help navigating our selection, our knowledgeable team is ready to provide expert assistance. We’ll work with you to find the perfect Olets that meet your technical specifications and ensure your project’s success