Branch Connection - Weldolet

High Quality Weldolet Branch Connection Manufacturer in Mumbai

Citizen Pipe Fittings offers Weldolet Branch Connection at best Price

Citizen Pipe Fittings, a distinguished manufacturer, exporter, and stockist, is recognized for its exceptional Weldolet Branch Connection. These fittings are an integral part of the company’s product portfolio, designed with precision and manufactured to perfection

A Weldolet Branch Connection is a type of branch fitting that provides a 90-degree branch connection from a main pipe. It is designed to be welded onto the run pipe, creating a strong and durable connection that can withstand high pressures and temperatures

As a manufacturer, Citizen Pipe Fittings utilizes state-of-the-art manufacturing processes and stringent quality control measures to ensure the robustness and reliability of each Weldolet Branch Connection. The fittings are crafted from high-quality materials that offer superior resistance to corrosion and wear, ensuring long-lasting performance

As an exporter, Citizen Pipe Fittings has established a strong global presence, delivering its top-quality Weldolet Branch Connection to various industries across the globe. The company’s commitment to maintaining international quality standards and providing timely delivery has earned it a reputation for reliability and excellence

As a stockist, Citizen Pipe Fittings maintains an extensive inventory of Weldolet Branch Connection in a variety of sizes and specifications. This enables the company to promptly cater to the diverse needs of its clients, ensuring minimal downtime in critical operations

Citizen Pipe Fittings, with its roles as a manufacturer, exporter, and stockist, stands as a trusted name in the industry for providing high-quality Weldolet Branch Connection. Their commitment to quality, customer satisfaction, and adherence to industry standards sets them apart in the competitive market

Types of Weldolet Branch Connection

Based on the information provided, there are two main types of Weldolet Branch Connection

- Standard Weldolets : These are also known as full-size weldolets. They are used to connect a branch line that is the same size as the header pipe

- Reducing Weldolets : These have a smaller branch size than the main header pipe. They are used when the branch pipe size is less than that of the run (header) pipe

Key features of Weldolet Branch Connection

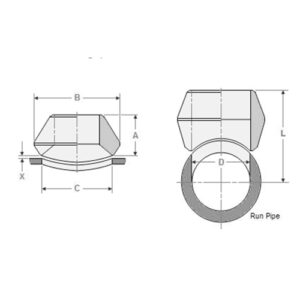

Weldolet Branch Connection are a type of branch connection fitting that are widely used in the piping industry. key features are- Design : Weldolets are designed to create 45 or 90 degrees integrally reinforced branch connections from a run pipe (also called, header pipe) to a branch pipe (outlet pipe). They have a beveled end that is prepared for welding

- Installation : On one side, the weldolet is fixed onto the run pipe with a full penetration groove weld and, on the other side, it is welded (or screwed) on the branch pipe

- Advantages : The use of weldolets instead of conventional fittings has several advantages. They require just 2 welds instead of 3, accelerating installation time. They also require less space, making the piping system design more flexible

- Flow : The flow is fully unrestricted, due to the funnel design

- Materials : Weldolets are manufactured in a wide range of forged steel materials: carbon steel, alloy steel, stainless steel, and nickel alloys

- Standards : The MSS-SP 97 specification covers the dimensions, the finishing, the tolerances, the testing methods and procedures, the marking, the material grades, and the minimum tensile strength requirements for weldolets

- Types : There are standard weldolets (full size) that are used to connect a branch line of the same size as the header pipe, and reducing weldolets which have a smaller branch than the main header pipe

- Strength : Weldolets provide extra support for the branch line and create a stronger welding connection than if the branch line was just welded onto the main pipe

Specifications

| Parameter | Description |

|---|---|

| Type | Weldolet |

| Connection | Butt-weld |

| Sizes | Ranging from 1/4” through 48” |

| Standards | Manufactured in accordance with ASME B16.11 |

| Design | Self-reinforced, minimizes stress concentrations |

| Ends | Beveled ends prepared for welding |

| Use | They are Used when a pipeline needs to be branched off |

| Installation | They are welded onto the main pipe and provides an opening for a branch line |

Grades

| Material | Grade |

|---|---|

| Carbon Steel | ASTM A105 (high-temperature), A350 LF2/LF3 ( low-temperature) |

| Alloy Steel | ASTM A182 Grades F5, F9, F11, F22 |

| Stainless Steel | ASTM A182 F304, F316 |

| Nickel Alloys | Inconel, Monel, Incoloy |

Applications

Weldolet Branch Connections are versatile fittings that find applications across a variety of industries. Here are some of the key sectors where they are commonly used :

- Oil and Gas Industry : Weldolets are extensively used in oil refineries, petrochemical plants, and offshore platforms. They facilitate the creation of branch connections in pipelines that transport hydrocarbons and other fluids

- Power Generation : Power plants employ Weldolets to establish connections in steam and water pipelines. These connections ensure efficient fluid flow and minimize turbulence, contributing to the overall efficiency of the power generation process

- Chemical Processing : In chemical processing plants, Weldolets are used in high-pressure applications. They provide a smooth transition from the main pipe to the branch pipe, facilitating efficient fluid or gas flow while minimizing turbulence

- Water Treatment Facilities : Weldolets are used in water treatment plants to create branch connections in pipelines. They help in the efficient distribution and flow of treated water

- Hot Construction Industry : In the construction sector, Weldolets are used in the piping systems of buildings and infrastructure. They provide a reliable and durable solution for creating branch connections in pipelines