Branch Connection - Flangolet

Flangolet Branch Connections: Manufacturer, Exporter in Mumbai

Flangolet Branch Connections offered by Citizen Pipe Fittings are designed for durability and Effeciency

The Flangolet Branch Connection is a unique and innovative product in the world of pipe fittings. It is designed to facilitate the connection between large-bore headers and flanged end components, making it an ideal choice for high-pressure piping systems

One of the standout features of the Flangolet Branch Connection is its 90-degree angle, which is specifically engineered to withstand high-pressure environments. This design not only enhances the efficiency of the connection but also significantly reduces the number of welded joints, offering a more streamlined and robust solution compared to traditional connections

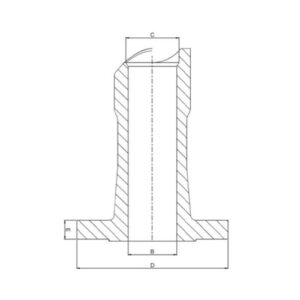

The Flangolet Branch Connection is available in a wide range of dimensions, from 1/2″ to 24″, catering to a variety of requirements. It also comes in different ratings, including 150#, 300#, 600#, 900#, and 1500#, to accommodate different pressure levels

In essence, the Flangolet Branch Connection exemplifies the commitment to quality, durability, and efficiency that is synonymous with its manufacturer. It is a testament to the continuous innovation in the field of pipe fittings

Types of Flangolet Branch Connections

The Flangolet Branch Connection, a specialized type of pipe fitting, comes in various forms to cater to different needs in the piping industry. Here are some of the types

- Standard Flangolet : This is the most common type, designed to connect large-bore headers and flanged end components. It’s ideal for high-pressure systems

- Reducing Flangolet : This type is used when there is a need to connect pipes of different sizes. It reduces the size from the header to the branch connection

- Short Pattern Flangolet : This variant has a shorter length than the standard flangolet. It’s used in compact spaces where the distance between the header and the branch connection is minimal

- Long Pattern Flangolet : As the name suggests, this type has a longer length and is used when the distance between the header and the branch connection is significant

- Heavy Duty Flangolet : This type is designed for high-pressure and high-temperature applications. It’s made from robust materials to withstand extreme conditions

- Light Duty Flangolet : This variant is used for low-pressure and low-temperature applications. It’s lighter and less robust than the heavy-duty type

Each type of Flangolet Branch Connection is designed with specific applications in mind, ensuring optimal performance and durability in various piping systems

Key Features of Flangolet Branch Connections

Flangolet, a type of Olet fitting, is a unique and versatile component used in piping systems. Key features are as follows- Connection Type : Flangolets are designed to connect a pipe with a flange to a pipe without a flange. This makes them particularly useful in diverse piping configurations

- Ease of Assembly and Disassembly : One of the standout features of Flangolets is their ease of assembly and disassembly. This makes them an excellent choice for applications where regular maintenance or repair is required

- High-Pressure Applications : Flangolets can be used in high-pressure piping systems. They provide a 90-degree branch connection, which is essential for many industrial processes

- Reduced Welded Joints : Compared to traditional Olet + Pipe + Flanges connections, Flangolets reduce the number of welded joints. This not only simplifies the installation process but also enhances the overall integrity and reliability of the piping system

- Versatility : Like other Olet fittings, Flangolets are available in various materials and sizes. This makes them adaptable to a wide range of applications and environments

While Flangolets offer many advantages, it’s crucial to select the right type of Olet fitting based on the specific requirements of your piping system

Applications

The Flangolet Branch Connection is a versatile fitting that finds its application in a wide range of industries due to its unique design and robust performance. Key applications are as follows

- Oil and Gas Industry : Flangolets are commonly used in pipeline systems for the transportation of crude oil, natural gas, and petroleum products

- Manufacturing and Food Processing : In these industries, Flangolets are used in pumps, valves, and vessels to ensure efficient flow and connection

- Industrial Waterworks : Flangolets are used in pipe connections in industrial waterworks, providing a reliable and efficient piping system

- Heat Exchangers and Heating Systems : These systems of all sizes use Flangolets for their high-pressure applications

- Mining Support : Flangolets are used in mining support systems, providing a strong and durable connection

- Nuclear Power Systems : In nuclear power systems, Flangolets are used due to their ability to withstand high-pressure environments

- Plumbing and Mechanical Systems : Flangolets are used in plumbing and mechanical systems for their versatility and reliability

- HVAC Systems : Flangolets are also used in HVAC systems for their ability to provide a smooth and seamless connection

- Pharmaceuticals and Food Processing Plants : In these industries, Flangolets are used for their ability to maintain a hygienic and efficient flow

The Flangolet Branch Connection is a combination of a Weldolet and a Flange, and it is used to connect pipelines with different diameters or to branch off pipelines. Proper installation of Flangolet is essential for a safe and efficient piping system

Specifications

| Specification | Description |

|---|---|

| Manufacture Standards | MSS SP-97, BS3799, ASME B16.11, GB19236 |

| Rate | 3000LBS~9000LBS / SCH10S ~ SCHXXS for butt-weld end |

| Dimension | 1/2” to 24” (DN15 ~DN600) |

| Types of Ends | ASME B16.11 (socket weld and threaded ends), ASME B16.25 (buttweld ends) |

Grades

| Material | Grade |

|---|---|

| Carbon Steel | ASTM A105, A350 LF2/LF3 |

| Alloy Steel | ASTM A182 Grades F5, F9, F11, F22 |

| Stainless Steel | SS grades, ASTM A182 F304, F316 |

| Nickel Alloys | Inconel, Monel, Incoloy, etc |