Branch Connection - Nipolet

Nipolets Branch Connection Manufacturer in India

Our Nipolets are known for their durability and performance, catering to various industries worldwide

Nipolet Branch Connections are a specialized type of branch connection extensively used in various industries. They have unique design and functionality.

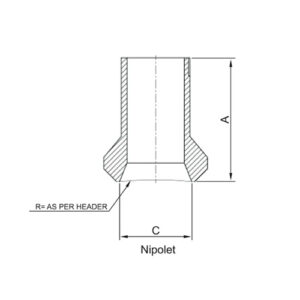

A Nipolet is a one-piece fitting that provides an outlet from a larger pipe to a smaller one (or could be the same size). The main pipe is of larger size onto which the branch connection is welded. Nipolets are used for valve take-offs, drains, and vents, and are available in a variety of materials to suit different applications

The design of a Nipolet ensures a strong, leak-proof connection, making it a preferred choice in industries where pipe integrity is paramount. They are commonly used in high-pressure systems and are designed to provide 90-degree branching from the main run of pipe

In essence, Nipolet Branch Connections are a reliable, cost-effective solution for creating strong, durable, and high-performing pipe connections in a wide range of industrial applications

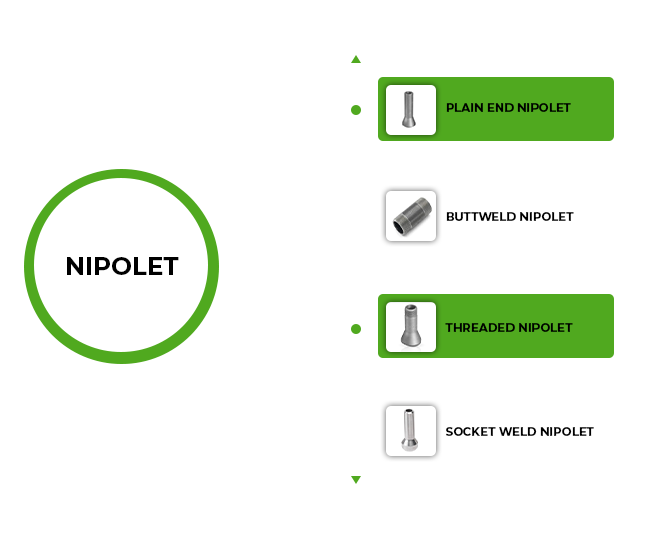

Types of Nipolet Branch Connections

Citizen pipe fittings provide Nipolet branch connections in various types to suit different applications. The key types are :

- Butt Weld Nipolet : This type of Nipolet is designed for butt welding applications. It is welded onto the run pipe, providing a secure and reliable connection

- Socket Weld Nipolet : Socket Weld Nipolets are manufactured with socket weld outlets on the branch pipe side. They are ideal for applications requiring a strong, leak-proof connection

- Threaded Nipolet : Threaded Nipolets come with threaded outlets on the branch pipe side. They are used in applications where a threaded connection is preferred for ease of installation and removal

- Plain End Nipolet : Plain End Nipolets are designed with a plain end on the branch pipe side. They are typically used in applications where the branch pipe will be connected using a different method, such as flanging or grooving

Each type of Nipolet is designed for specific applications and connection methods, so it’s important to select the right type for your specific needs

Key Features of Nipolet Branch Connection

Nipolet branch connections are a type of Olet fitting that have several key features :- Integrally Reinforced Branch Connections : Nipolets are designed to create 45 or 90 degrees integrally reinforced branch connections from a run pipe (also called, header pipe) to a branch pipe (outlet pipe). This makes them a reliable choice for creating branch connections in piping systems

- High Strength : Nipolets are forged products, which gives them high strength. This makes them suitable for use in high-pressure applications

- Ease of Installation : Nipolets can be easily installed on the run pipe with a full penetration groove weld. This makes them a convenient choice for many piping applications

- Unrestricted Flow : The design of Nipolets allows for fully unrestricted flow, due to the funnel design. This makes them ideal for applications where clean and purified fluids need to flow through with minimum turbulence

- Versatility : Nipolets are available in a wide range of sizes, types/designs, and connection types (buttweld, socket weld, threaded), and in a wide range of forged steel materials. This makes them a versatile choice for a variety of piping applications

- Compliance with Standards : The connection resulting from using Nipolets complies with ASME B31.1 and ASME B31.3 power and process piping codes

Applications

Nipolet branch connections, a type of Olet fitting, are used in various applications in the piping industry. Their key applications are

- Valve Take-Off : Nipolets are often used for valve take-off applications. This involves creating a branch connection from a main pipe to a valve. The Nipolet is welded onto the main pipe, providing a secure and reliable connection

- Drains and Vents : Another common application of Nipolets is in the creation of drains and vents. These are essential components of many piping systems, allowing for the safe and efficient removal of waste or excess materials

- High-Point Vent and Low-Point Drain Systems : Nipolets are used in high-point vent and low-point drain systems. These systems are designed to remove air or gas trapped at the highest point of the piping system (high-point vent) and to drain liquid from the lowest point (low-point drain)

- Small-Diameter Branch Connections : Nipolets are ideal for applications requiring small-diameter branch connections. They are designed to connect a pipe at a 90-degree angle to a smaller diameter pipe, making them well-suited for low-pressure applications

- Purified Fluid Flow : Nipolets are also used in piping systems where clean, purified fluids need to flow through with minimal turbulence. Their design and structure make them a perfect fit for such applications

The choice between Nipolets and other types of Olet fittings depends on the specific requirements of your project, including the size of the pipes, the pressure of the system, and the type of fluid being transported

Specifications

| Specification | Description |

|---|---|

| Connection Type | Available with male-socket-weld or male threaded outlets |

| Size Range | 1/2" – 2" (preferred size range) |

| Rating | 3000#, 6000# |

| Length | Extra Strong, Double Extra Strong applications in 3.1/2in to 6.1/2in lengths |

| End | Female threaded or Socket weld end |

| Branch Component End | Male threaded or Plain end |

Grades

| Material | Grade |

|---|---|

| Carbon Steel | A350 LF2/LF3 for low-temperature, ASTM A105 for high-temperature |

| Alloy Steel | ASTM A182 Grades F5, F9, F11, F22 |

| Stainless Steel | ASTM A182, F316, F304 and other SS grades |

| Nickel Alloys | Inconel, Monel, Incoloy, etc |