The integration of blind flanges in solar plants is a pivotal advancement in enhancing operational efficiency and system reliability. These specialized components are crucial for managing and maintaining the integrity of fluid conveyance systems often used in cooling processes or heat transfer mediums within solar power facilities. Here, we explore how blind flanges, including stainless steel blind flanges, threaded blind flanges, and ASME blind flanges, play a vital role in the streamlined operation of solar plants

Understanding Blind Flanges

What Are Blind Flanges?

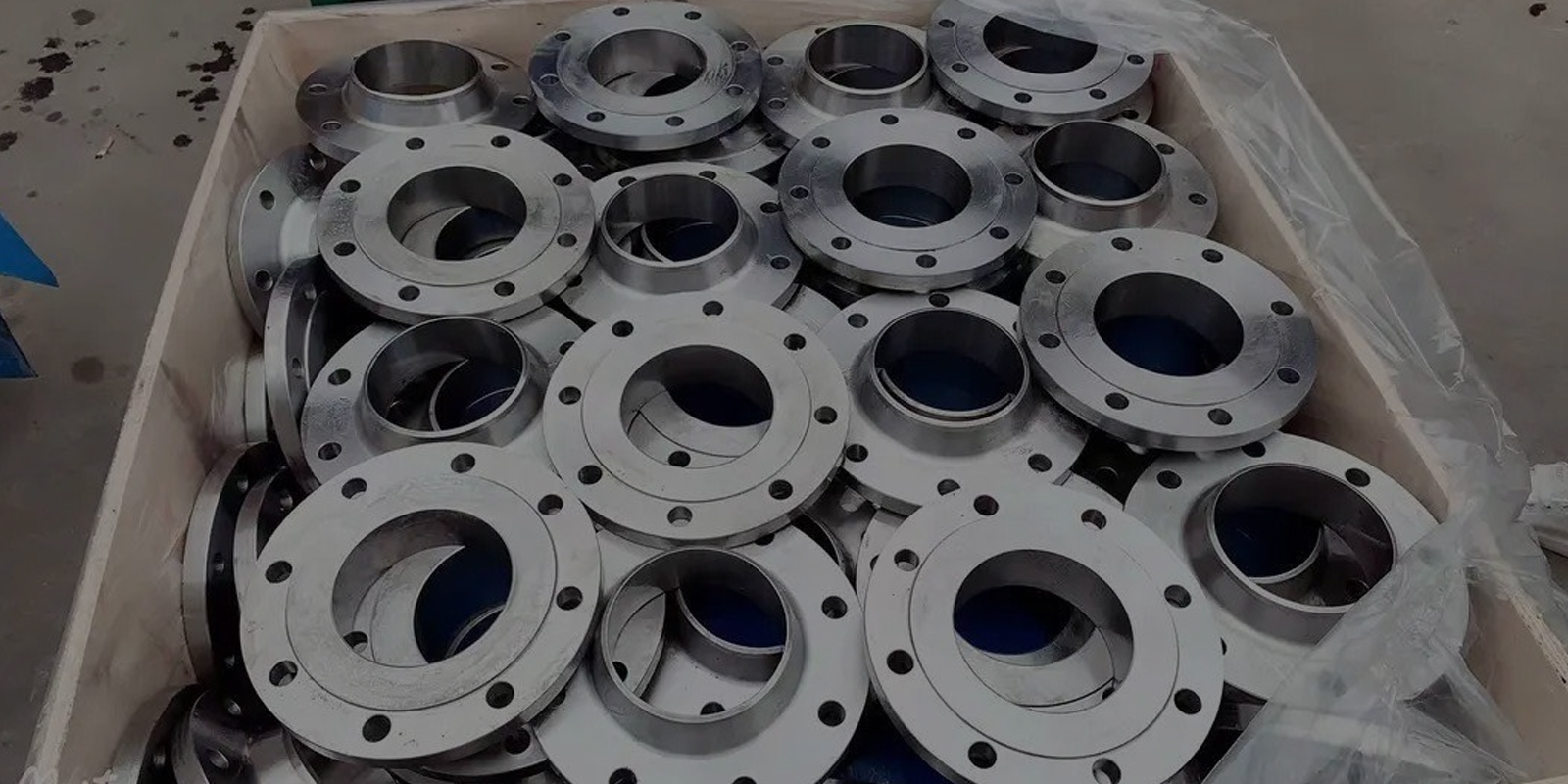

Blind flanges are solid plates designed to close the end of piping systems. A valve used to halt the flow of steam or gas is easy to take out for inspection and preservation. Their versatility also makes them a must-have in solar power installations where system robustness and ease of maintenance are major factors

Types of Blind Flanges

- Stainless Steel Blind Flange : The solar industry highly prefers stainless steel blind flanges due to their excellent corrosion resistance and mechanical strength. These qualities give them the perfect profile for outdoor use, especially in solar plants, under the sun, rain, dust, and UV exposure. Because of the durable nature of stainless steel, these flanges can handle these conditions without risk of corrosion or wearing down as the years pass. It helps the piping systems of the solar plant stand up to the harsh environment, conserving the integrity and durability of the facility's piping systems.

- Threaded Blind Flange : Threaded blind flanges are advantageous in the modular structure of solar plants. They are threaded pipe flanges and they can be attached to other threaded pipe flanges without the need for welding. This feature makes the process of installation easy and allows for faster changes or additions to the system. Threaded Blind Flanges — In cases requiring either fast deployment or where reconfigurations are common, the use of threaded blind flanges can lead to reduced labor costs and less system downtime, resulting in incremental operational efficiencies. This design saves much time during maintenance or emergency repair and allows quick interruption of the system during maintenance or repair.

- ASME Blind Flange : ASME blind flanges are manufactured to the exacting standards of the American Society of Mechanical Engineers. These standards help standardize the flanges, keeping them compliant with high-pressure conditions common in solar thermal systems where heat transfer fluids are held at several hundred psi and hundreds of degrees to effectively create steam and power. Blind flanges that are ASME certified are reliably strong and completely safe in operation, important considerations in high-performance applications

Role of Blind Flanges in Solar Plants

In solar power plants, blind flanges are effectively used for several essential applications that contribute to keeping the fluid handling systems intact and performing efficiently. These are used to plug pipes and valves and to leak-proof and tamper-proof the system. This sealing capacity is indispensable if a part of the system needs to be separated from the entire operation, e.g. during maintenance or system testing. Additionally, during emergencies, isolated flanges can immediately cut off areas of the plant from damage or system fluid loss, aiding in safety and preventing downtime

Improving Efficiency With The Help Of Blind Flanges

In solar power plants, blind flanges play an essential role in increasing system efficiency. They allow the plant to be disconnected and reconnected in segments that make it possible for scheduled maintenance and repairs to be completed without long plant shutdowns. Downtime is thereby minimized and the plant benefits from running longer in top efficiency. Blind flanges are also found in the pipeline and are used to seal off a specific section of the pipeline, while plate flanges are used to connect two different pipes. Their role in this is to facilitate rapid changes and upgrades to the system to get you installed and operational quickly but to also continuously improve the solar plant’s performance as additional technologies and methodologies allow

Material and Design Considerations

Flanges are made of many materials, often given a specific material to be able to make them in the installation environment, and the material along with the support has good corrosion resistance. They are normally fabricated of stainless steel, due to its good corrosion resistance and strength, although other materials may also be used in manufacture, including carbon or alloy steel, depending on the need for thermal conductance or cost. Other factors that the design of the flange depends on are the pressure and temperature at which the system will operate, the types of fluids that will go through the system, and of course the environmental conditions. Threaded blind flanges can be a good option for low-pressure applications with a need for rapid dismantling and reinstallation. However, ASME blind flanges are necessary for high-pressure systems because of their durability and their adherence to safety standards

Advantages in the Long Run

When installed in solar plants, using blind flanges can provide the following primary advantages: Since they are more durable and can preserve a tighter seal, they typically have a much longer shelf life and need to be replaced far less often, leading to lower maintenance costs over the life of the plant. This producibility significantly improves safety, as the workforce or environment is now far less likely to be at risk in the event of a system cache failure

Choosing the Right Blind Flange Supplier

- Importance of a Reliable Supplier : Selecting the right blind flanges supplier is crucial. A reliable supplier ensures high-quality products that meet industry standards and are suitable for the specific environmental conditions of a solar plant.

- What to Look for in a Supplier : When choosing a blind flanges supplier, consider their industry reputation, the quality of the materials they use, their pricing, and their ability to provide custom solutions if necessary. It's also beneficial to choose suppliers who have specific experience with renewable energy projects

Conclusion

Incorporating blind flanges in solar plants is not just about improving efficiency and reliability; it’s also about ensuring the longevity and safety of the entire operation. From stainless steel blind flanges to threaded blind flanges and ASME blind flanges, each type serves a critical function in maintaining the high standards required in solar power production. As solar technology advances, the role of these components will only grow more significant, underpinning the scalable and sustainable expansion of solar energy projects worldwide

Choosing the right blind flanges supplier is essential to achieving these goals, making it a key factor in the success of any solar plant project

Contact sales@citizenpipefittings.com to consult with our team at Citizen Pipe Fittings for advice on Blind Flanges and choosing the right components for your project