In the world of piping and instrumentation, it is critical to guarantee the proper and safe functioning of the systems. One of the key factors that can be employed in this regard is the spectacle blind flanges. These are very useful fittings that are used to separate a part of a pipeline or a process system for maintenance, repair, or modification without the danger of leakage or contamination. In this article, the author is going to discuss how spectacle blind flanges are used, installed, and why they are so important in different industries

Understanding Spectacle Blind Flanges

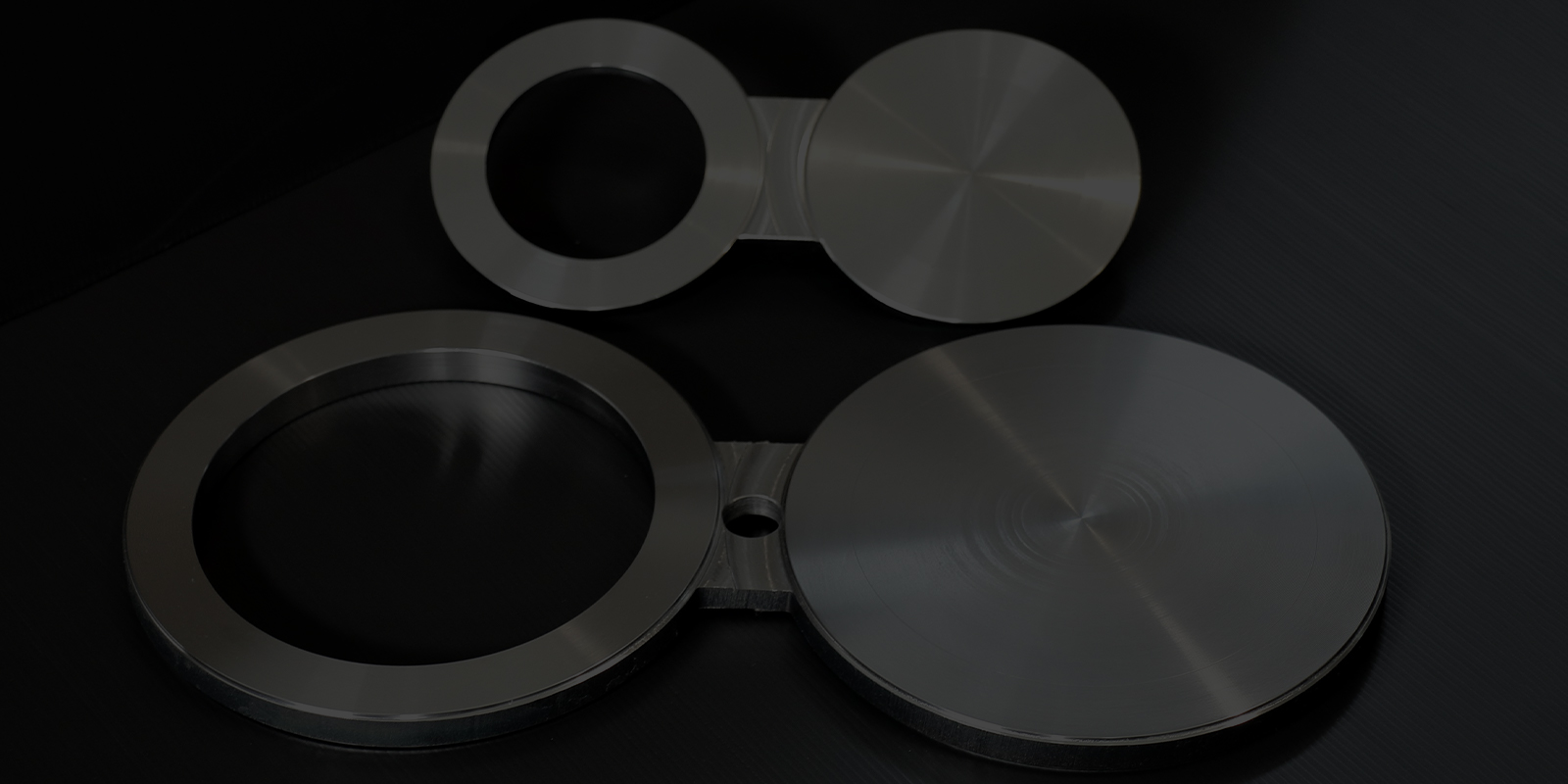

A spectacle blind flange, spectacle blind or spec blind flange is a safety device that is applied to isolate a segment of a pipeline. It is made of two circular metal pieces having a small portion of metal in between that looks like a pair of spectacles. One disc is a solid plate while the other is a ring through which the flow of the pipe is achieved. The solid plate can be rotated into position to block flow while the ring allows it to pass; this makes it easy to control flow during maintenance or inspection

Spectacle blinds are regulated by standards such as ASME B16. 48 Spectacle Flange and ANSI B16. 48 Spectacle Flange, they are standardized for design, dimension and material to provide safety and reliability for their applications

Installation and Operation

The installation of spectacle blind flanges requires precision and adherence to safety protocols. Here are the steps involved in installing and operating spectacle blinds

- Bolting : Pass the bolts through the holes that are in line and then tighten the bolts evenly. It is important to tighten the bolts to the manufacturer’s recommended torque specifications; use a torque wrench to do this. This makes the connection to be secure and no leakage of information that is being transferred.

- Operation : To stop the flow, turn the solid plate of the spectacle blind to the side of the pipeline. To allow flow, turn the ring into this position. Make sure that the spectacle blind does not shift from the two positions in any way by accident.

- Inspection : Check the spectacle blind and the respective flanges for signs of wear, corrosion or damage at least once a week. Any part that appears to have worn out should be replaced to ensure that the isolation system is as effective as required

Positioning the Spectacle Blind Flange

Place the spectacle blind between the two flanges of the pipeline section. Ensure that the bolt holes of the spectacle blind align with those of the flanges

- Testing and Verification : After installation, test the system to ensure there are no leaks and that the spectacle blind is functioning correctly. Regular testing and verification are crucial for maintaining the system integrity.

- Preparation and Safety : Ensure that the section of the pipeline where the spectacle blind will be fitted has no pressure and is empty. Confirm that the spectacle blind meets the necessary ASME B16.48 Spectacle Flange or ANSI B16.48 Spectacle Flange standards. Wear appropriate safety gear and follow all safety protocols to prevent accidents.

- Switching Positions : To stop the flow, turn the solid plate of the spectacle blind into the pipeline. To allow flow, turn the ring into this position. Ensure that the spectacle blind does not shift from the two positions accidentally.

- Documentation and Labeling : Record any changes made during the installation or maintenance process. Proper documentation helps track the history of maintenance and ensures compliance with industry standards. Label the spectacle blind flange clearly to indicate its current position (open or blind) and any other relevant information

Conclusion

Spectacle blind flanges play a vital role in ensuring the safety, efficiency, and reliability of pipeline systems across various industries. By understanding their application, installation, and benefits, you can make informed decisions about integrating them into your operations. Adhering to ASME B16.48 Spectacle Flange and ANSI B16.48 Spectacle Flange standards ensures that you are using high-quality, reliable components. Whether for maintenance, safety, or operational flexibility, spectacle blinds from trusted suppliers like Citizen Pipe Fittings are indispensable in modern piping systems

You can Contact Citizen Pipe Fittings at sales@citizenpipefittings.com to learn more about Spectacle Blind Flanges and how they can be used in industrial operations.