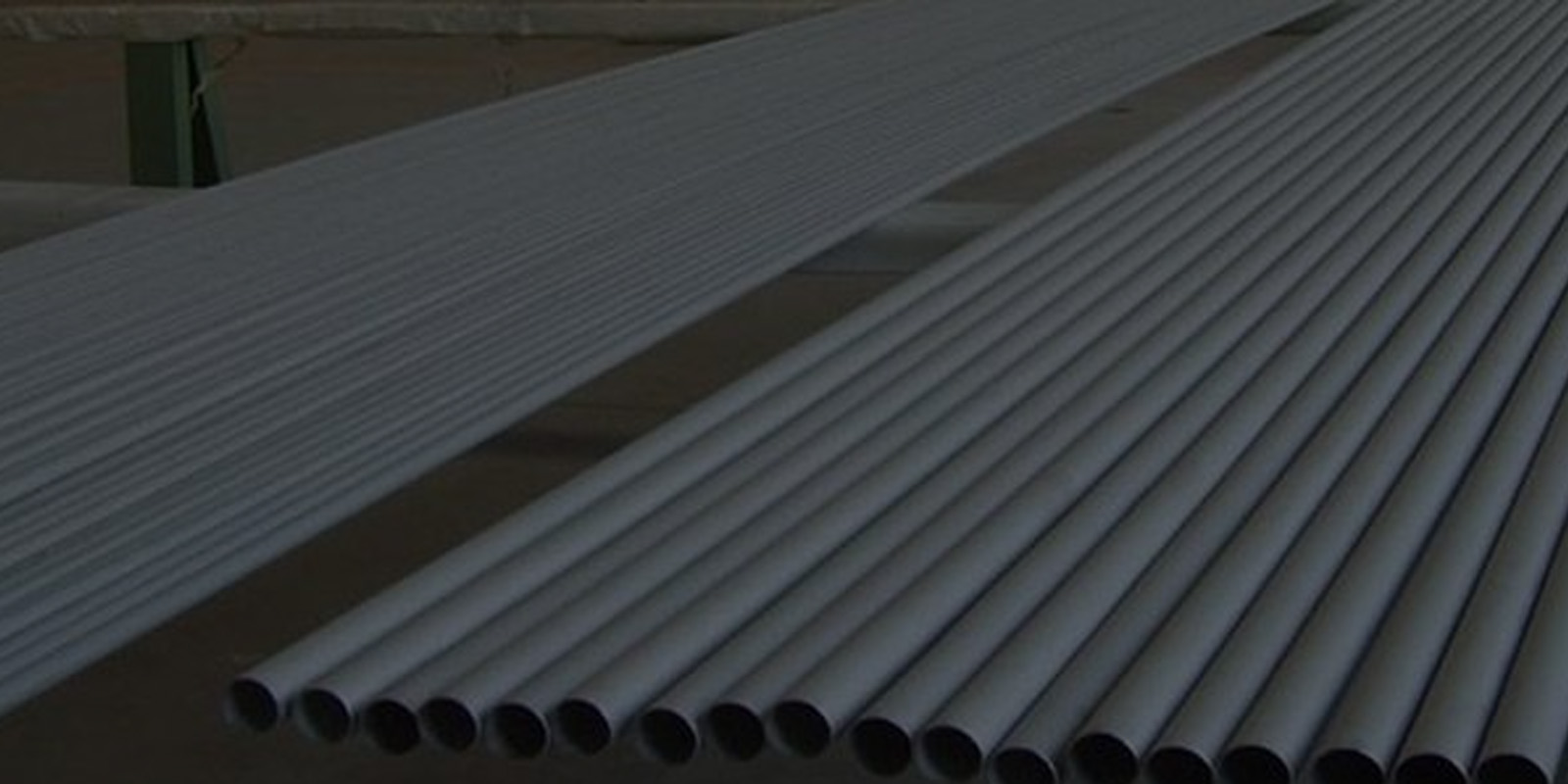

In the realm of industrial piping, Duplex Steel Seamless Pipes have emerged as a revolutionary solution, offering unmatched strength, corrosion resistance, and durability. Over the years, technological advancements have significantly enhanced the production and application of these pipes, making them a preferred choice across various industries, including oil and gas, chemical processing, and marine engineering. This blog delves into the innovations that have shaped the evolution of Duplex Steel Seamless Pipes and the implications for manufacturers, exporters, and end-users

The Rise of Duplex Steel

Let us first discuss what makes Duplex Steel so unique before we discuss the innovations. Duplex Steel is a material that has the desirable characteristics of both the austenitic and the ferritic stainless steel. This combination makes the material to have high corrosion resistance, high strength and high weldability. These pipes are smooth and do not have any welded joints which are likely to develop cracks and compromise the strength of the pipe. Due to the increasing need of industries for stronger and more reliable material, Duplex Steel Seamless Pipes have been in high demand and this has made manufacturers to look for better ways to produce the pipes

Advancements in Manufacturing Techniques

The production of Duplex Steel Seamless Pipes has also undergone some changes especially in the areas of accuracy and productivity. The most significant development is the application of sophisticated hot and cold working procedures. These methods have helped the manufacturers to achieve closer tolerances in the pipes they produce and this has helped in the production of pipes that meet the required standards in the market

Another significant change is the use of automation in the production line of the company. Automation also helps to increase the rate of production and at the same time, it eliminates the chances of making mistakes, thus, the quality of the product is improved. For instance, rolling mills and extrusion processes have been automated and made to be more precise in order to produce pipes with better dimensions and surface finish

Also, improvements in non-destructive testing (NDT) have revolutionized the quality assurance of Duplex Steel Seamless Pipes. Ultrasonic testing and radiographic inspection, which are some of the advanced NDT techniques, can identify even the tiniest of flaws in the pipe material so that only the best products are sold to the public

Enhanced Corrosion Resistance

Industries prefer using Duplex Steel Seamless Pipes mainly because of its high resistance to corrosion. New technologies have even more developed this characteristic. With the improvement in the composition of the alloy, new grades of Duplex Steel have been produced that are more resistant to such forms of corrosion as pitting, crevice corrosion, and stress corrosion cracking

Also, surface treatment technologies have developed and can apply protective coatings that make the corrosion resistance of Duplex Steel pipes even better. These coatings, which are usually applied using such methods as plasma spraying or electrochemical deposition, serve as an extra layer of protection against hostile environments and, therefore, increase the service life of the pipes

Sustainability and Environmental Impact

Sustainability is now an important factor in industries in the current world. Duplex Steel Seamless Pipes have also not been spared from this trend of production. There have been improvements in the recycling and waste management thus making the manufacturing process more sustainable. For instance, the contemporary steel industries have adopted the closed-loop recycling where scrap metal and other wastes are recycled within the production line thus minimizing on raw materials and wastes

In addition, new technologies in the production of the Duplex Steel Seamless Pipes have also led to low emission of carbon in the manufacturing process. Low temperature forming and energy efficient heat treatment methods have been adopted and used in the production of pipes with high quality using less energy

Applications and Future Prospects

As a Duplex Steel Seamless Pipes Manufacturer, Citizen Pipe Fittings is at the forefront of delivering high-performance piping solutions to various industries. The innovations discussed above have expanded the range of applications for Duplex Steel Seamless Pipes, making them indispensable in sectors where reliability and longevity are paramount

For instance, in the oil and gas industry, these pipes are now commonly used in subsea pipelines, where their superior strength and corrosion resistance are crucial. Similarly, in chemical processing plants, Duplex Steel Seamless Pipes are favored for their ability to withstand highly corrosive environments while maintaining structural integrity

Looking ahead, the future of Duplex Steel Seamless Pipes technology holds even more promise. Ongoing research and development efforts are focused on creating new grades of Duplex Steel with enhanced properties, such as increased toughness and resistance to even more extreme environments. Additionally, innovations in pipe forming and welding technologies are expected to further improve the quality and performance of these pipes

Conclusion

The story of Duplex Steel Seamless Pipes from being a specialized product to becoming an essential commodity of the industrial world is the story of innovation. As a Duplex Steel Seamless Pipes Exporter, Citizen Pipe Fittings has not only adopted to these technologies but also makes sure that their products cater to the dynamic needs of the global industries

You can Contact Citizen Pipe Fittings at sales@citizenpipefittings.com to know more about Duplex Stainless Steel Pipes and how they can be used in various industries.