In the current world of industries, there is a need for products that will be able to endure harsh environments. Of these, Super Duplex Steel flanges have turned into an essential component for several applications. Their high strength coupled with high corrosion resistance makes them suitable for use in industries that are exposed to unfavorable conditions. These flanges are used in the oil and gas industry, chemical processing, and even in marine applications and these flanges are very important in the reliability and safety of the systems

Understanding Super Duplex Steel Flanges

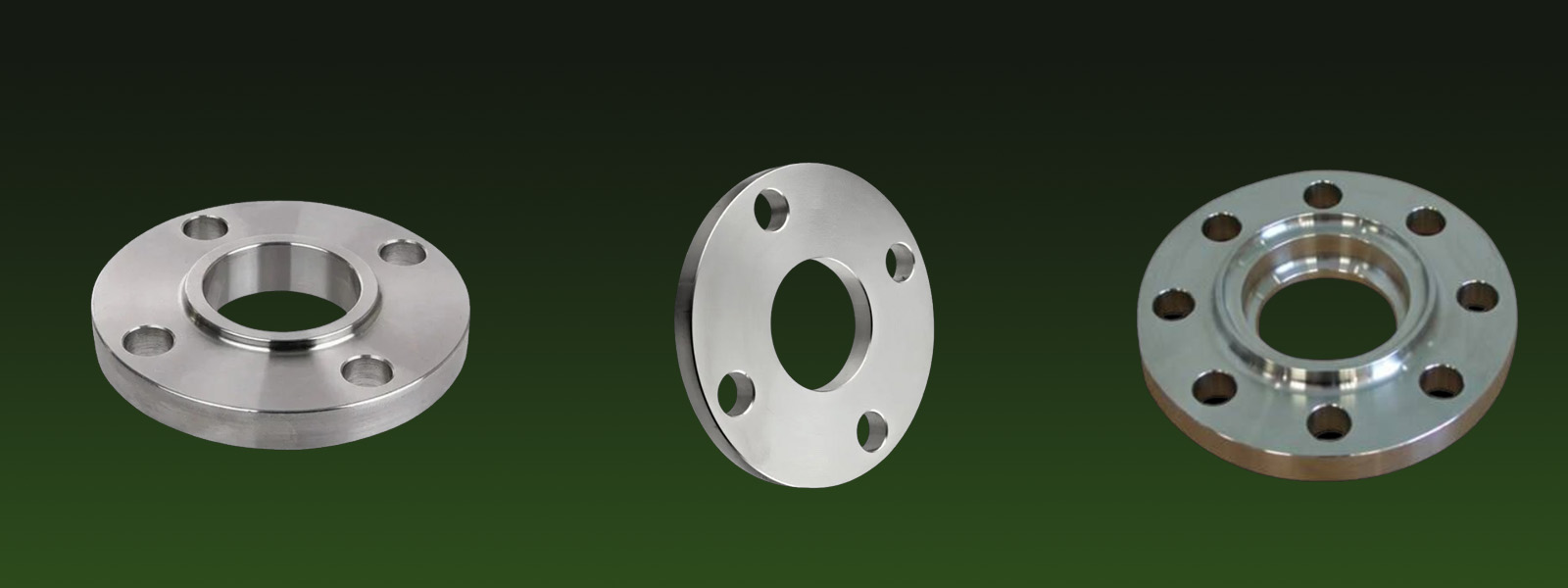

To give a clear understanding of these flanges before going to their applications, the following are the factors that define them. Super Duplex Steel is an austenitic-ferritic stainless steel that possesses a combination of characteristics that are not found in other stainless steels. It has a dual-phase microstructure of both austenite and ferrite and thus has good strength and also good resistance to corrosion. This material is particularly appreciated for its low susceptibility to pitting and crevice corrosion, particularly in chloride-containing environments. Such characteristics make Super Duplex Steel suitable for flanges, which are essential parts of the piping system

Flanges are used to join pipes, valves, pumps, and other equipment in order to create a system of piping. They afford easy accessibility for cleaning, inspection, and making changes when necessary. Super Duplex Steel pipe flange is used in those industries where normal stainless steel or other material cannot withstand the operating conditions

Key Real-Life Applications

1. Oil and Gas Industry

The oil and gas industry is one of the most challenging industries for the application of materials. Here, pipelines convey a number of fluids that may be under high pressure and in corrosive conditions. The flanges and fittings used in this industry are Super Duplex Steel because of their high-pressure tolerance and resistance to corrosive fluids

In offshore oil platforms, for example, the presence of seawater can be highly corrosive to metals. Super Duplex Steel’s superior resistance to saltwater corrosion makes it the material of choice for flanges used in these environments. These flanges ensure the integrity of connections in the pipelines that carry oil and gas from the seabed to the surface

2. Chemical Processing Plants

Chemical processing entails the use of different aggressive chemicals such as acids, alkalis and solvents among others. In such areas, the materials that are used have to be able to withstand corrosion and have to possess high strength. Super Duplex Steel flanges fulfil these requirements and are therefore an essential component in chemical processing plants

For example, in the production of fertilizers, sulfuric acid is used and its handling poses a great danger. Sulfuric acid is highly corrosive and therefore any material used in the production of the acid must be highly resistant. Super Duplex Steel flanges are useful in providing the much-needed strength so that pipelines do not leak or fail under difficult circumstances

3. Marine Applications

Marine application is another area where ASTM a182 Super Duplex Steel flanges are highly suitable. Marine structures such as ships, submarines and offshore platforms are always in contact with seawater which is a well-known corrosive medium. Super Duplex Steel also has high strength and corrosion resistance making it suitable to be used in marine structures

These flanges are widely utilized in the fabrication of the piping systems of ships where they play the role of minimizing the risks of fluid transportation. Further, in the desalination plants where seawater is treated to make it potable, Super Duplex Steel flanges are employed in high-pressure pumps and pipes through which the seawater is transported in the various stages of the process

4. Desalination Plants

As the availability of fresh water is reducing day by day, desalination plants have become crucial in many regions of the world. These plants work on the basis of desalination of seawater to get fresh water free from salt and other pollutants. It involves high pressures and the use of salt water and therefore materials used in the process must be able to handle such conditions

Super Duplex Steel flanges are suitable for this application because of their high corrosion resistance and high strength even under high pressure. These flanges are used in different stages of the desalination process to make sure that the system is leakproof and effective

5. Pulp and Paper Industry

The pulp and paper industry may not be the first to come to mind when thinking of harsh environments, but the chemicals used in the production process can be highly corrosive. Chlorine dioxide, used in bleaching, is one such chemical that requires materials with high corrosion resistance

In this industry, Super Duplex Steel flanges and fittings are used in pipelines that transport these corrosive chemicals. Their resistance to both chlorine-induced stress corrosion cracking and general corrosion makes them indispensable in ensuring the longevity and reliability of the production equipment

Conclusion

Super Duplex Steel flanges have proven to be an invaluable asset in various industries due to their exceptional strength and corrosion resistance. Whether in the oil and gas sector, chemical processing plants, marine applications, or even in the pulp and paper industry, these flanges are crucial for ensuring the safety and efficiency of piping systems

By choosing astm a182 Super Duplex Steel for flanges, industries can benefit from reduced maintenance costs, longer service life, and improved safety. As industrial demands continue to grow, the importance of reliable materials like Super Duplex Steel flanges will only become more pronounced, solidifying their role as a cornerstone in modern industry

You can Contact Citizen Pipe Fittings at sales@citizenpipefittings.com to know more about Super Duplex Steel Flanges and their applications in various industries.