Slip-On Flanges Manufacturer And Exporter

Designed for superior performance and longevity

Citizen Pipe Fittings a trusted manufacturer and stockist based in Mumbai, India, offers a variety of pipe fittings and flanges, including Slip-on Flanges. These flanges are designed to slide over the end of the pipe and are then welded in place, providing a secure and leak-resistant connection between pipes or fittings in a piping system.

Citizen’s Slip-on Flanges are known for their quality and durability, making them a preferred choice for various industrial applications. They are available in different types of materials and grades to cater to the specific requirements of the application

Slip-on flanges, often referred to as SO flanges, are typically made of forged materials and are designed to slide over the end of piping and then welded in place. These flanges are ideal for lower pressure applications as they can be easily fitted and welded into different pipes. The integrity of the welded area can be easily examined by radiography. The bore of the pipe and flange are both the same which reduces turbulence and erosion inside the pipeline. The simplicity of welding and ease of installation makes slip-on flanges an ideal choice for many applications

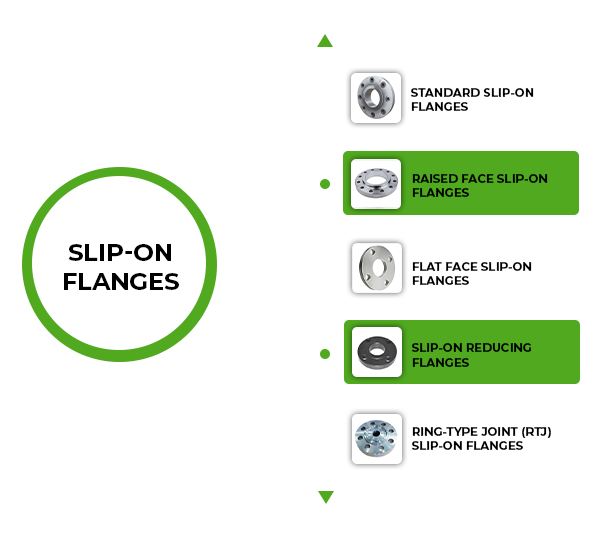

Types of Slip-on Flanges

Slip-on flanges come in various types, each designed to meet specific piping requirements. Here are the main types of slip-on flanges

- Standard Slip-On Flanges : These are the most common type of slip-on flanges. They are designed to slide over the pipe and are then welded in place, providing a secure and leak-resistant connection

- Raised Face Slip-On Flanges : These flanges have a raised face around the bore, which is used to create a seal between two flanges. The raised face helps to prevent the fluid or gas from leaking out of the pipeline

- Flat Face Slip-On Flanges : These flanges are similar to the raised face slip-on flanges, but they have a flat face. They are typically used in applications where the mating flange or flanged fitting is made from a material that cannot be easily welded

- Slip-On Reducing Flanges : These flanges are used when there is a need to change the pipe diameter. They are designed to slide over the larger pipe and are then welded in place

- Ring-Type Joint (RTJ) Slip-On Flanges : These flanges have a grooved ring on their surface for a better seal. They are used in high-pressure applications

Key Features of Slip-on Flanges

Slip-on flanges are widely used in various industries due to their unique features. Here are some key features of slip-on flanges- Ease of Installation : Slip-on flanges are designed to slide over the pipe, making them easy to install

- Cost-Effective : Compared to other types of flanges, slip-on flanges are usually more cost-effective due to their simpler design and lower material requirement

- Versatility : They can be used with different types of pipes, including seamless, ERW, EFW, and welded pipes

- Durability : Despite their simple design, slip-on flanges are known for their durability and can withstand high pressure, temperature, and mechanical stress

- Leak-Proof : When properly installed, slip-on flanges provide a tight and leak-proof seal, making them ideal for applications that require a secure connection

Applications

They are widely used across various industries due to their ease of installation, cost-effectiveness, and significant strength. Some of the key applications of slip-on flanges in different industries are

- Low-Pressure Applications : SOFs are extensively used in low-pressure applications. They provide a secure connection between two pipes that can withstand high pressures and does not leak

- Water Systems : SOFs are commonly used in water systems. They allow for easy access for inspection or maintenance since they can be removed without having to cut into the pipe itself

- Oil and Gas Pipelines : SOFs are frequently used in oil and gas pipelines. They are particularly helpful when liquid or gas flows from a smaller to a larger diameter

- Air Conditioning Systems and Cooling Towers : SOFs are used in air conditioning systems and cooling towers. They occupy minimum longitudinal space for a flange and come in a wide range of diameters

- Chemical and Petrochemical Plants : SOFs are common in chemical and petrochemical plants. They are designed in various configurations, such as oval or round, and have different thicknesses from 6mm to 100mm thick, as per the client’s prerequisites and specifications

- Pharmaceuticals : SOFs find applications in the pharmaceutical industry. They are manufactured from carbon steel, stainless steel, and aluminum alloys with features that influence their viability for diverse sorts of pipelines or installations based on factors like temperature range and corrosion resistance levels

Specifications

| Specification | Description |

|---|---|

| Size | 1/2"NB to 56"NB |

| Class | 150#, 300#, 3000#, 6000#, 9000# |

| Pressure Ratings | PN 1 - PN 400 |

| Standards | DIN 86029, ASTM A105, ASTM A182, ASME B16.5, BS 3293 |

| Material Types | Stainless Steel, Alloy Steel, Carbon Steel |

| Flange face type | RF, RTJ |

Grades

| Material | Grade |

|---|---|

| Carbon Steel | ASTM A10523 |

| Alloy Steel | F11, F2223 |

| Stainless Steel | F304/F304L, F316/F316L23 |