Leading Manufacturer of Superior Reducing Flanges

Superior Quality Reducing Flanges manufactured for high Durability and Efficiency

Citizen Pipe Fittings a renowned name in the industry, presents its distinguished line of Reducing Flanges. These flanges are meticulously designed to connect pipes of different sizes, facilitating a smooth and efficient transition in the flow of a fluid. Crafted with precision, they ensure a tight and leak-proof connection, enhancing the overall efficiency of your piping system

The Reducing Flanges by Citizen Pipe Fittings are not just functional components; they are a testament to the company’s commitment to quality and innovation. Made from durable materials, these flanges are built to withstand high pressure and temperature, promising longevity and reliability

Whether you’re dealing with complex industrial systems or simple residential plumbing, Citizen’s Reducing Flanges are the perfect solution for seamless pipe size transitions. Their easy installation and maintenance make them a preferred choice for professionals and DIY enthusiasts alike. Experience the blend of quality, functionality, and innovation with Reducing Flanges by Citizen Pipe Fittings. Your piping systems deserve nothing less

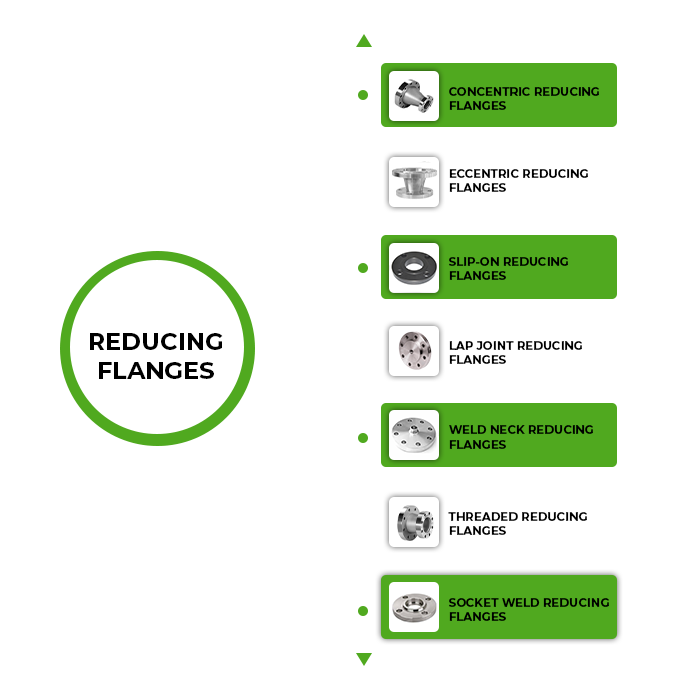

Types of Reducing Flanges

Reducing Flanges, a key component in piping systems, come in a variety of types to cater to different needs. Here are some of the types offered by Citizen Pipe Fittings :

- Concentric Reducing Flanges : These flanges have a common center line. They are used when there is a need to maintain the same top or bottom center line. These are often used in vertical piping systems

- Eccentric Reducing Flanges : Unlike concentric flanges, these do not have a common center line. They are used in horizontal piping systems to maintain the bottom or top alignment

- Slip-On Reducing Flanges : These flanges are slipped over the pipe and then welded both inside and outside to provide sufficient strength and prevent leakage. They are best suited for lower pressure applications

- Weld Neck Reducing Flanges : These flanges are distinguished by their protruding necks. The pipe is welded to the neck of the flange, which helps in transferring stress from the flange to the pipe itself. This type of flange is used in high-pressure and high-temperature applications

- Threaded Reducing Flanges : These flanges are used for pipes with external threads. The benefit of these flanges is that they can be attached without welding, making them ideal for extremely high-pressure applications

- Socket Weld Reducing Flanges : These flanges are used for small-size high-pressure piping. The pipe is inserted into the socket end and then fillet-welded

- Lap Joint Reducing Flanges : These are essentially slip-on flanges, but with the added feature of a radius at the intersection of the flange face and the bore to accommodate a lap stub end. They are used in systems requiring frequent dismantling for inspection and cleaning

Each type of Reducing Flange has its unique advantages and uses, making them suitable for a wide range of applications in various industries

Key Features of Reducing Flanges

Reducing Flanges by Citizen Pipe Fittings are designed with a host of key features that make them an indispensable component in any piping system. Here are some of the standout features- Versatility : Reducing Flanges are designed to connect pipes of different diameters, making them highly versatile in various applications

- Durability : Made from robust materials, these flanges can withstand high pressure and temperature conditions, ensuring long-lasting performance

- Leak-Proof Design : The precision-engineered design ensures a tight and leak-proof connection, preventing any fluid leakage

- Ease of Installation : Reducing Flanges are easy to install and maintain, making them a preferred choice for both professionals and DIY enthusiasts

- High Compatibility : They are compatible with various types of pipes, enhancing their usability across different systems

- Improved Flow Control : By facilitating smooth transitions in pipe sizes, Reducing Flanges help in maintaining an efficient flow of fluid

- Quality Assurance : As a product of Citizen Pipe Fittings, these flanges come with a guarantee of quality and reliability

These features collectively contribute to the superior performance and reliability of Reducing Flanges by Citizen Pipe Fittings, making them a valuable addition to any piping system

Applications

Reducing Flanges by Citizen Pipe Fittings find their applications in a wide range of industries due to their versatile nature and robust design. The key applications are :

- Petrochemical Industry : Reducing Flanges are used in the petrochemical industry for connecting pipes of different sizes, facilitating the smooth flow of chemicals and other substances

- Water Treatment Plants : These flanges are used in water treatment plants for connecting pipes and ensuring a leak-proof system

- Power Generation : In power generation plants, Reducing Flanges are used in the piping systems that carry steam or water

- Food and Beverage Industry : These flanges are used in the food and beverage industry to ensure hygienic and efficient transfer of liquids

- Pharmaceutical Industry : In the pharmaceutical industry, Reducing Flanges are used in the piping systems that carry gases and liquids

- Construction : In the construction industry, these flanges are used in the plumbing systems of buildings

- Shipbuilding : Reducing Flanges are used in the shipbuilding industry in the piping systems for carrying fuel, water, and other fluids

- HVAC Systems : These flanges are used in Heating, Ventilation, and Air Conditioning (HVAC) systems for connecting pipes of different sizes

The versatility and robustness of Reducing Flanges by Citizen Pipe Fittings make them suitable for a wide range of applications, delivering efficiency and reliability in various industries

Specifications

| Parameter | Description |

|---|---|

| Size | 1/2" NB TO 48" NB |

| Class | 2500#, 1500#, 150#, 300#, 400#, 600#, 900# |

| Standard | MSS SP44, ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48 |

| Type | Socket Weld, Lap Joint , Slip-On, Weld Neck, Threaded |

| Face Type | Ring Type Joint (RTJ) , Flat Face (FF), Raised Face (RF) |

Grades

| Material | Grade |

|---|---|

| Stainless Steel | ASTM A 182, A 240 904L, F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347 and 347H |

| Duplex Steel | ASTM / ASME A/SA 182 F 61, F 44, F 45, F51, F 53, F 55 and F 60 |

| Carbon Steel | ASTM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F91, F1, F5, F9, F11, F12 and F22 |

| Nickel Alloy | ASTM / ASME SB 564 / 160 / 472, Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |