Weld Neck Flanges Manufacturer and Stockist in Mumbai

Designed for durability and efficiency, perfect for your piping needs

Citizen Pipe Fittings, a leading manufacturer in India, offers a comprehensive range of flanges, including Weld Neck Flanges. These flanges are designed with an emphasis on precision, durability, and functionality. The Weld Neck Flanges by Citizen are characterized by a neck that extends from the flange, transferring stress from the flange to the pipe itself. This unique design reduces the pressure concentration at the base of the flange, making these flanges an excellent choice for handling systems operating under high or low temperatures and high pressure

Citizen’s Weld Neck Flanges are typically supplied with flat face (FF), raised face (RF), and ring type joint (RTJ) options. The raised face option features a height on the flange, while the RTJ face is designed to contain a gasket ring, making it suitable for high-pressure applications. These flanges are made from Duplex 2205 stainless steel, ensuring robustness and longevity. The flanges conform to international standards such as ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, and NACE

Whether you’re looking for flanges for aerospace applications, nuclear engineering, the chemical industry, or heat treating industry, Citizen’s Weld Neck Flanges are a reliable and versatile choice. Remember, it’s important to consider the appropriate flange features, material, dimensions, and class to meet your application needs

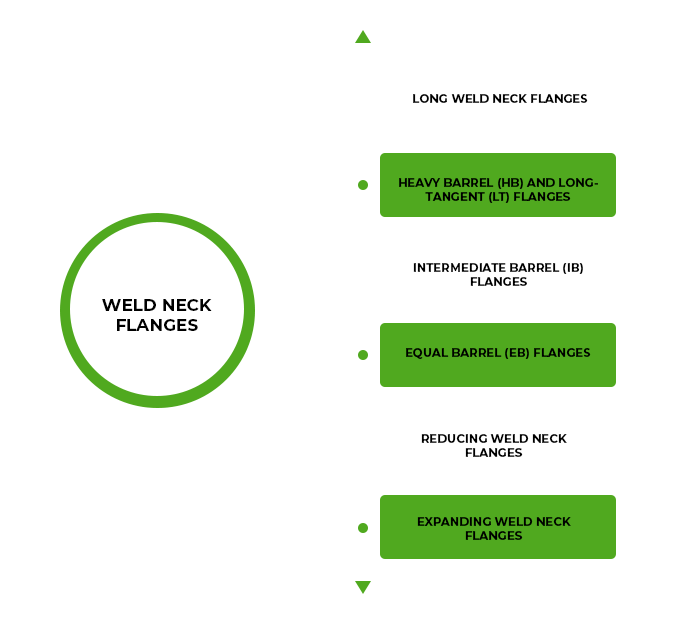

Types of Weld Neck Flanges

Weld neck flanges are a critical component in various industrial applications, particularly in the piping industry. They are known for their distinct design and robustness. Here are some of the types of weld neck flanges:

- Long Weld Neck Flanges : These flanges are distinguished by their elongated tapered hub. They are often used in high-pressure applications due to their ability to handle stress

- Heavy Barrel (HB) and Long-Tangent (LT) Flanges : HB and LT flanges have a thicker wall and a longer hub, respectively. They are typically used in high-pressure and high-temperature applications

- Intermediate Barrel (IB) Flanges : These flanges have a medium-length tapered hub and are used in applications that require a balance between strength and form factor

- Equal Barrel (EB) Flanges : EB flanges have a hub length equal to the flange’s diameter. They are commonly used in applications where space is limited

- Reducing Weld Neck Flanges : These flanges are used to connect pipes of different diameters. They have a tapered hub that transitions from a larger diameter (flange side) to a smaller diameter (pipe side)

- Expanding Weld Neck Flanges : The opposite of reducing flanges, these flanges transition from a smaller diameter (flange side) to a larger diameter (pipe side). They are used to increase the pipe size in a piping system

The selection of the appropriate type of weld neck flange depends on the specific requirements of your application, including factors like pressure, temperature, and flow rate

Key features of Weld Neck Flanges

Weld Neck Flanges are a type of pipe flange with a unique design and specific features. Here are some key features- Design : Weld Neck Flanges are characterized by a neck that extends from the flange, transferring stress from the flange to the pipe itself. This unique design reduces the pressure concentration at the base of the flange

- Function : The primary function of Weld Neck Flanges is to connect valves with pipelines that operate under high pressure. They are also used in pipelines that transmit valuable, inflammable, or explosive media

- Installation : ld Neck Flanges are butt welded to a pipe. The rim has a number of drilled holes that allows the flange to be fixed to another flange with bolts

- Material : Weld Neck Flanges are commonly made from materials like carbon alloy and stainless steel. The choice of material usually matches the material of the connecting pipe

- Dimensions : Weld Neck Flanges are available in various sizes, ranging from 1/2” to 48”, and classes from 150 LBS to 2500 LBS. The flanges conform to international standards such as ASTM, ASME, API, AISI, BS, ANSI, DIN, JIS, MSSP, and NACE

- Uses : Weld Neck Flanges are often used when long service is required from components. They provide high performance, strength, and reliability for indoor and outdoor applications

When choosing Weld Neck Flanges, it’s important to consider the appropriate flange features, material, dimensions, and class to meet your application needs

Applications

Weld Neck Flanges, with their unique design and robust construction, find applications across a wide range of industries. Here are some of the key applications

- Oil and Gas Industry : Weld Neck Flanges are extensively used in the oil and gas industry. They are employed for connecting pipelines, transmission systems, and offshore platforms. Their ability to withstand high temperatures and pressures makes them ideal for this industry

- Chemical and Petrochemical Industry : In the chemical and petrochemical industries, Weld Neck Flanges are used for transporting corrosive fluids and gases. They help in preventing leaks and ensuring safe and efficient operation

- Power Generation Industry : Weld Neck Flanges are recommended for high-pressure steam handling systems commonly used in power generation facilities. They provide a secure and reliable connection, ensuring the smooth operation of power plants

- Water Treatment Industry : In water treatment plants, Weld Neck Flanges are used for their superior leak protection, durability, and strength. They ensure a secure and leak-proof connection, which is crucial in water treatment processes

- Other Industries : Apart from the above, Weld Neck Flanges also find applications in other industries such as pharmaceuticals, energy, and agriculture. The reliability of Weld Neck Flanges make them a preferred choice across various sectors

Specifications

| Parameter | Description |

|---|---|

| Size | Ranges from 1/2" to 60" |

| Pressure Class | 150#, 300#, 400#, 600#, 900#, 1500#, 2500# |

| Facing | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Standards | MSS SP44 , ANSI B16.48, ANSI B16.36, ANSI B16.5, ANSI B16.47 |

| Material | Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel, Nickel Alloys |

Grades

| Material | Grade |

|---|---|

| Carbon Steel | ASTM A105, A350 LF2, LF3 |

| Stainless Steel | ASTM A182 F304, F304L, F316, F316L, F321 |

| Alloy Steel | ASTM A182 F91, F1, F5, F9, F11, F22 |

| Duplex Steel | ASTM A182 F51, F53, F55, F60 |

| Nickel Alloys | Hastelloy C22, C276 , Monel 400 & 500, Inconel 600 & 625, Incoloy 800, 825 |