Premium Socket Weld Flanges Manufacturer

Discover the high-quality and robust Socket Weld Flanges by Citizen Pipe Fittings

Citizen Pipe Fittings is a renowned manufacturer of industrial pipe fittings, including Socket Weld Flanges. Their Socket Weld Flanges are designed with precision and crafted from high-quality materials to ensure durability and reliability in various industrial applications

The Socket Weld Flanges from Citizen Pipe Fittings are known for their robust construction and excellent resistance to corrosion, making them suitable for use in harsh environments. They are available in various sizes and pressure ratings, catering to a wide range of piping systems. One of the distinguishing features of Citizen Pipe Fittings’ Socket Weld Flanges is the internal recess or socket. This design allows for a pipe to be inserted into the flange and then fillet welded, ensuring a smooth bore and better fluid flow

These flanges are ideal for small-sized high-pressure piping systems due to their high fatigue strength. Moreover, their ease of alignment during installation makes them a preferred choice in the industry. However, they are not suitable for piping systems with a fluctuating temperature as it may lead to leakage due to thermal expansion

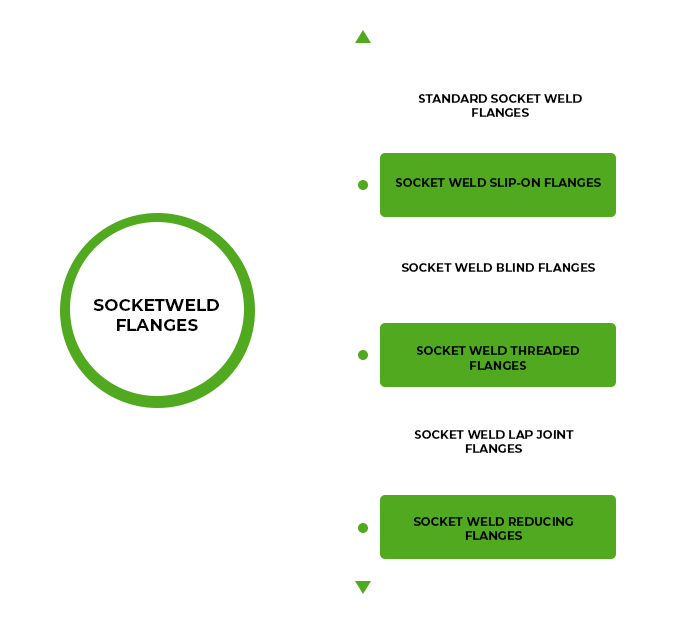

Types of Socket Weld Flanges

Socket Weld Flanges are a versatile and widely used flange type in various industries. Here are some of the types of Socket Weld Flanges

- Standard Socket Weld Flanges : These are the most common type of Socket Weld Flanges, used in a variety of applications. They have a recessed area for inserting the pipe before welding, ensuring a smooth bore and better fluid flow

- Socket Weld Slip-On Flanges : These flanges are similar to standard slip-on flanges, but with a socket for welding. They are easier to install and align compared to standard Socket Weld Flanges

- Socket Weld Blind Flanges : These flanges are used to seal the end of piping systems or pressure vessel openings. They have a socket for welding and are typically used for testing the flow of gas or liquid in a pipeline

- Socket Weld Threaded Flanges : These flanges have a threaded bore, allowing them to be attached to pipes with external threads. They are used in applications where welding is not suitable

- Socket Weld Lap Joint Flanges : These flanges are used with a matching stub-end insert. They are ideal for systems that require frequent dismantling for inspection and cleaning

- Socket Weld Reducing Flanges : These flanges are used to connect pipes of different diameters. They have a larger socket size on one side for the larger pipe, and a smaller socket on the other side for the smaller pipe

Key features of Socket Weld Flanges

- Design : Socket Weld Flanges have a recessed area for inserting the pipe. This design allows for a smooth bore and better fluid flow when the pipe is used in a high-pressure piping system

- Strength : They are known for their high structural strength, making them ideal for high-pressure systems and hazardous applications

- Size Variety : These flanges come in a variety of sizes to accommodate different pipe diameters, making them versatile for various applications

- Easy Installation : The installation process of Socket Weld Flanges is straightforward. The pipe is inserted into the socket of the flange upto the shoulder of the socket. Then, it is positioned and welded in place

- Leakage Prevention : The internal weld on these flanges helps prevent leakage, making them an excellent choice for applications where preventing leaks is crucial

- Durability : Socket Weld Flanges are highly durable and can withstand high temperatures and pressures. They are also resistant to shock and vibration, contributing to their longevity

- Maintenance : These flanges are easy to inspect and maintain due to their accessible design

Applications

- Oil and Gas Industry : Socket Weld Flanges are commonly used in the oil and gas industry due to their ability to withstand high pressures and temperatures. They are often used in pipelines and tanks that carry oil, gas, and other hazardous materials

- Chemical Industry : These flanges are used in chemical plants for their leak-proof design. They are ideal for systems that carry corrosive chemicals and high-temperature fluids

- Power Generation : In power plants, Socket Weld Flanges are used in high-pressure systems such as steam lines and feedwater lines. Their durability and strength make them suitable for these demanding applications

- Pharmaceutical Industry : The pharmaceutical industry uses these flanges in their piping systems to maintain a sterile environment. Their leak-proof design helps prevent contamination

- Food and Beverage Industry : Socket Weld Flanges are used in the food and beverage industry in systems that require sanitary conditions. They are easy to clean and maintain, which is crucial in this industry

- Water Treatment Plants : These flanges are used in water treatment plants in systems that handle water at high pressures. Their leak-proof design helps prevent water loss

- Shipbuilding Industry : In the shipbuilding industry, Socket Weld Flanges are used in piping systems that carry fuel, water, and hydraulic fluids. Their ability to withstand shock and vibration makes them ideal for this application

Specifications

| Specification | Description |

|---|---|

| Size | Ranges from 1/2" to 48" |

| Standards | AWWA, Custom Drawings, ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605 |

| Pressure Ratings | Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class 2500 |

| Facing Method | Raised Face (RF), Ring Type Joint (RTJ), Large Male-Female (LMF), Small Male-Female (SMF), Large Tongue & Groove, Small Tongue & Groove |

| Form | Socket Welding Flanges, Slip-On Flanges, Blind Flanges, Lap Joint Flanges, Threaded Flanges, Plate Flanges |

Grades

| Material | Grade |

|---|---|

| Stainless Steel | ASTM A 182, A 240 F 904L, 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H |

| Duplex & Super Duplex Steel | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60 and F 61 |

| Carbon Steel | ASTM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65 and F70 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F91, F1, F5, F9, F11, F12 and F22 |

| Nickel Alloy | ASTM / ASME SB 564 / 472/ 160 / Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |