Leading Manufacturer and Stockist of Superior Orifice Flanges

Superior Quality Orifice Flanges manufactured for high Durability and Efficiency

Orifice Flanges by Citizen Pipe Fittings are known for their superior quality, durability, and excellent performance. They are specifically designed to provide unrestricted flow of fluid, making them an ideal choice for applications that require precise flow control

These flanges are made from high-grade materials, ensuring their ability to withstand extreme conditions and pressures. They are available in various sizes and specifications, catering to the unique requirements of each project

Citizen Pipe Fittings takes pride in their commitment to quality and customer satisfaction. Their Orifice Flanges are a testament to their dedication to providing reliable and efficient solutions to their clients

Orifice Flanges are specialized flanges used in conjunction with orifice meters to measure the flow rate of liquids or gases through a pipeline. They play a crucial role in the field of fluid dynamics and are widely used across various industries

The unique design of Orifice Flanges allows for the precise measurement of flow rates. They feature a small hole, or ‘orifice’, in the center, which creates a pressure differential as fluid flows through it

Orifice Flanges are typically used in pairs with orifice plates sandwiched between them. This assembly is then mounted in the pipeline. The flanges themselves are designed with tapped holes, allowing for the connection of pressure gauges or other measurement devices

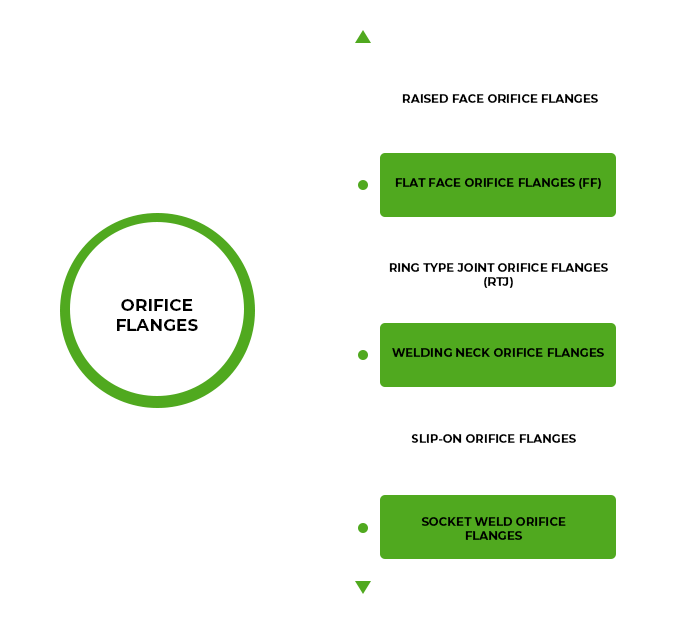

Types of Orifice Flanges

Orifice flanges are used in various industries, including oil and gas, for measuring the flow rate of liquids or gases in a pipeline. They are a crucial component in flow control systems. Here are the main types of orifice flanges

- Raised Face Orifice Flanges (RF) : These flanges have a small raised surface around the bore which provides a sealing surface. They are the most common type of orifice flange used in industrial applications

- Flat Face Orifice Flanges (FF) : These flanges have a flat face and are typically used in low-pressure systems where leakage is not a concern

- Ring Type Joint Orifice Flanges (RTJ) : These flanges have a grooved face for a metal ring gasket. They are used in high-pressure applications

- Welding Neck Orifice Flanges : These flanges are designed to be welded to the pipe. They are often used in high-pressure systems due to their strong and durable design

- Slip-On Orifice Flanges : These flanges are slipped over the pipe and then welded. They are used in lower pressure applications and are easier to install than welding neck flanges

- Socket Weld Orifice Flanges : These flanges have a socket in which the pipe is inserted and then welded. They are used in small-sized high-pressure pipelines

Each type of orifice flange has its own advantages and is suited to specific types of applications. The choice of flange depends on the requirements of the system, including the pressure, temperature, and flow rate

Key Features of Orifice Flanges

Orifice flanges are a vital component in many industrial applications, particularly in the measurement and control of fluid flow. Here are some key features of orifice flanges

- Versatility : Orifice flanges can be used with a variety of liquids and gases, making them versatile for different industrial applications

- Flow Measurement : They are primarily used for flow measurement of gases, vapors, and liquids. They can also be used for flow restriction and pressure reduction

- Design : Orifice flanges are designed to accept orifice plates, which are used to measure the flow rate. The orifice plate, which is mounted between a pair of orifice flanges, creates a pressure differential as fluid flows through it. This pressure differential can be measured and used to calculate the flow rate

- Pressure Tappings : Orifice flanges usually come with tapped holes on either side of the orifice plate. These holes, or pressure tappings, allow for the connection of measurement instruments

- Material Selection : Orifice flanges can be made from a variety of materials to suit different applications and environments.They include carbon steel, stainless steel, and alloy steel

- Standards : Orifice flanges are manufactured according to certain standards, such as the ANSI B16.36 standard, to ensure quality and compatibility

- Sizes : They are available in a range of sizes to accommodate different pipe diameters

- Ease of Installation : Orifice flanges are relatively easy to install and can be used in both new and existing piping systems

Applications

Orifice flanges are widely used across various industries due to their ability to measure flow rates accurately. Here are some of the key applications

- Oil and Gas Industry : Orifice flanges are extensively used in the oil and gas industry for flow measurement, especially in upstream operations where accurate measurement of crude oil and natural gas is critical

- Petrochemical Industry : In petrochemical plants, orifice flanges are used to measure the flow of various chemicals during the manufacturing process. This helps in maintaining the right proportions and ensuring product quality

- Power Generation : In power plants, especially those using steam turbines, orifice flanges are used to measure the flow of steam. This helps in efficient power generation and reduces wastage

- Water Treatment Plants : Orifice flanges are used in water treatment plants to measure the flow of water and other liquids. This helps in monitoring and controlling the treatment process

- Food and Beverage Industry : In the food and beverage industry, orifice flanges are used to measure the flow of various liquids such as juices, dairy products, and even semi-solids like sauces and pastes

- Pharmaceutical Industry : In pharmaceutical manufacturing, orifice flanges are used to measure the flow of various liquids and gases during the production process. This ensures accurate dosing and mixing of ingredients

- HVAC Systems : Orifice flanges are used in Heating, Ventilation, and Air Conditioning (HVAC) systems to measure the flow of air and refrigerants. This helps in maintaining the right temperature and humidity levels

These are just a few examples of the many applications of orifice flanges. Their versatility and accuracy make them an essential component in many industrial processes

Specifications

| Parameter | Description |

|---|---|

| Size | Ranges from 1/2" to 24" |

| Class / Pressure | 2500#, 1500#, 900#, 150#, 300#, 600#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Flange Face Type | Ring Type Joint (RTJ) , Flat Face (FF), Raised Face (RF) |

| Standards | AWWA, Custom Drawings, ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605 |

| Dimension | AWWA, Custom Drawings, ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605 |

Grades

| Material | Grade |

|---|---|

| Stainless Steel | ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321 and 321H, 317, 347, 347H and 904L |

| Duplex & Super Duplex Steel | ASTM / ASME A/SA 182 F 44, F 45, F51, F 53 and F 55, F 60 and F 61 |

| Carbon Steel | ASTM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65 and F70 |

| Alloy Steel | ASTM / ASME A/SA 182 & A 387 F91, F1, F5, F9, F11, F12, F22 |

| Nickel Alloy | Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020) |