Branch Connection - Sweepolet

Sweepolet Branch Connections Manufacturer And Exporter

High Quality Sweepolet Branch Connection Exporter in Mumbai-Citizen Pipe Fittings

Citizen Pipe Fittings, a world leader in Branch Connection Manufacturing, offers the Sweepolet Branch Connection, a unique and innovative product in their lineup. The Sweepolet is a contoured, integrally reinforced, butt-weld branch connection designed for low stress and long fatigue life

This fitting is used to provide an outlet from a larger pipe to a smaller one. The attachment weld on the run pipe side can be easily examined by radiography, ultrasound, and other standard non-destructive techniques, ensuring the integrity of the connection

The Sweepolet Branch Connection is compatible with various materials such as Stainless Steel, Duplex Steel, and Nickel Alloys, making it a versatile choice for diverse piping needs

In summary, the Sweepolet Branch Connection by Citizen Pipe Fittings is a robust, versatile, and high-quality solution for various pipe connection requirements. Its unique design and features make it a standout product in the realm of pipe fittings

Types of Sweepolet Branch Connection

The Sweepolet Branch Connection offered by Citizen Pipe Fittings comes in various types based on the method of connection. Here are the primary types :

- Socket Weld (S/W) Sweepolet : This type of Sweepolet is connected to the run pipe via a socket weld. It’s a popular choice for small pipe diameters

- Screwed (SCRD) Sweepolet : This type involves a threaded connection between the Sweepolet and the run pipe. It’s commonly used for low pressure, non-critical applications

Each type of Sweepolet Branch Connection is designed to cater to specific requirements, offering flexibility and efficiency in various piping systems

Key Features of Sweepolet Branch Connection

The Sweepolet Branch Connection, a specialized product from Citizen Pipe Fittings, has several key features that make it a standout choice :- Contoured Design : The Sweepolet is a contoured, integrally reinforced, butt-weld branch connection, designed for low stress and long fatigue life

- Versatile Connection : This fitting is used to provide an outlet from a larger pipe to a smaller one, making it a versatile solution for various piping requirements

- Examination of Weld : The attachment weld on the run pipe side can be easily examined by radiography, ultrasound, and other standard non-destructive techniques, ensuring the integrity of the connection

- Material Compatibility : The Sweepolet Branch Connection is compatible with various materials such as Stainless Steel, Duplex Steel, and Nickel Alloys, making it a versatile choice for diverse piping needs

The Sweepolet Branch Connection is a robust, versatile, and high-quality solution for various pipe connection requirements. Its unique design and features make it a standout product in the realm of pipe fittings

Applications

Sweepolet Branch Connections are utilized in a variety of industries due to their unique design and functionality. Their key applications are ;

- Oil and Gas Industry : Sweepolets are extensively used in high-pressure gas and oil piping systems. They are particularly useful when handling corrosive and high-temperature materials

- Pipe Branch Fittings : Sweepolets serve as an efficient solution for connecting smaller pipe sizes to larger ones in piping systems. Their design simplifies the process of attaching branches to pipelines

- Refineries and Chemical Plants : In these settings, Sweepolets are commonly used due to their ability to improve fluid flow within pipelines, thereby reducing erosion and corrosion

- Offshore Platforms : The durability and ease of installation of Sweepolets make them a preferred choice for offshore platforms

- Energy Efficiency : The streamlined flow path of Sweepolets reduces pressure drops and energy losses, enhancing the overall efficiency of the system

- Ease of Installation and Maintenance : Sweepolets eliminate the need for reinforcement pads, reducing installation time and cost. Their design also simplifies maintenance procedures

These applications highlight the versatility and efficiency of Sweepolet Branch Connections in various industrial settings. Their unique design and high-quality materials contribute to their wide range of uses

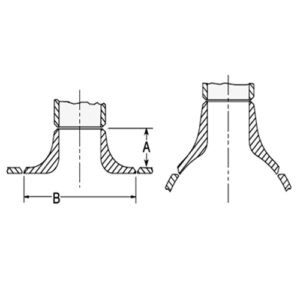

Specifications

| Run Size | Outlet Size | Dimensions A | Dimensions B |

|---|---|---|---|

| 6 to 36 | 1 1/4 | 1 1/4 | 4 |

| 6 to 36 | 1 1/2 | 1 3/4 | 5 1/2 |

| 6 to 36 | 2 | 1 1/2 | 5 1/2 |

| 6 to 36 | 3 | 1 21/32 | 7 |

| 6 to 36 | 4 | 2 1/32 | 8 3/4 |

| 10 to 36 | 6 | 2 11/16 | 13 |

| 12 to 36 | 8 | 3 | 15 |

| 16 to 36 | 10 | 3 1/8 | 18 1/2 |

| 16 to 36 | 12 | 3 5/16 | 20 1/2 |

| 20 to 36 | 14 | 3 5/8 | 24 |

| 24 to 36 | 16 | 3 3/4 | 28 |

| 24 to 36 | 18 | 4 5/8 | 31 |

| 24 to 36 | 20 | 5 1/8 | 33 |

| 30 to 36 | 24 | 5 5/8 | 38 |

Grades

| Material | Grade | Applications |

|---|---|---|

| Stainless Steel | 304, 316 | Due to its corrosion resistance and durability they are used in a variety of applications |

| Carbon Steel | A105, A350 LF2 | Commonly used in high-temperature and high-pressure applications |

| Alloy Steel | A182 F1, F5, F9, F11, F22, F91 | Known for their strength and resistance to wear, making them suitable for long-term operation |